Memjet has unveiled DuraFlex, it’s new modular single-pass print solution.

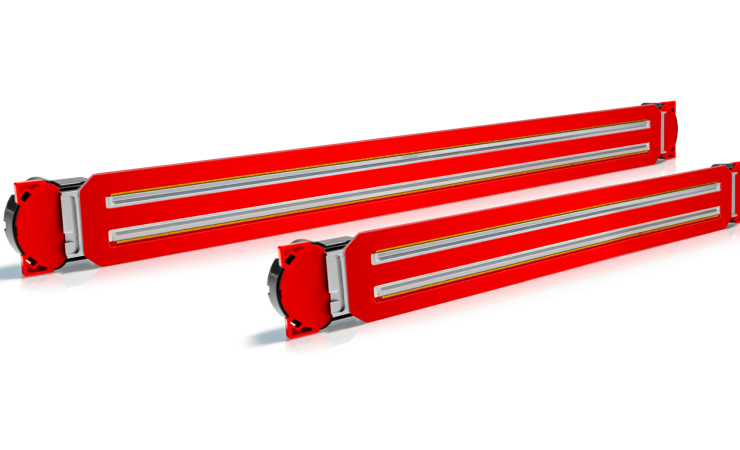

DuraFlex combines speed, simplicity and affordability with new attributes such as enhanced durability, A4 and A3 plus widths in a four-color printhead, a high-speed data path and modules that control all printhead functions.

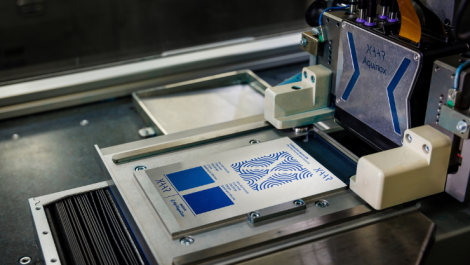

These features give OEMs the resources to create affordable benchtop, mini-press and entry-level presses capable of quality and speed previously not available in these types of solutions.

‘Our goal with designing DuraFlex was to create a simple yet robust technology that could give OEM partners the resources to create affordable printing solutions that were powerful, yet affordable,’ said Kim Beswick, general manager of Memjet’s benchtop and mini-press division.

‘DuraFlex delivers on this goal. With its compact, modular design, category-leading speed, 1600dpi quality and economical cost, DuraFlex provides partners robust resources for creating benchtop and entry-level label and packaging presses as well as other light production and wide-format print and packaging applications.’

With 1600 x 1600dpi and built-in nozzle redundancy, DuraFlex operates at print speeds up to 46m/min. It uses aqueous pigment inks that are lightfast, water durable and scratch resistant. These inks have been developed for use in indirect food contact applications and are compatible across a broad range of porous, uncoated offset, inkjet treated and inkjet coated media.

Memjet will showcase the capabilities of this new technology at Labelexpo.