Colordyne Technologies is set to develop an aqueous pigment engine using Memjet’s DuraFlex printhead technology.

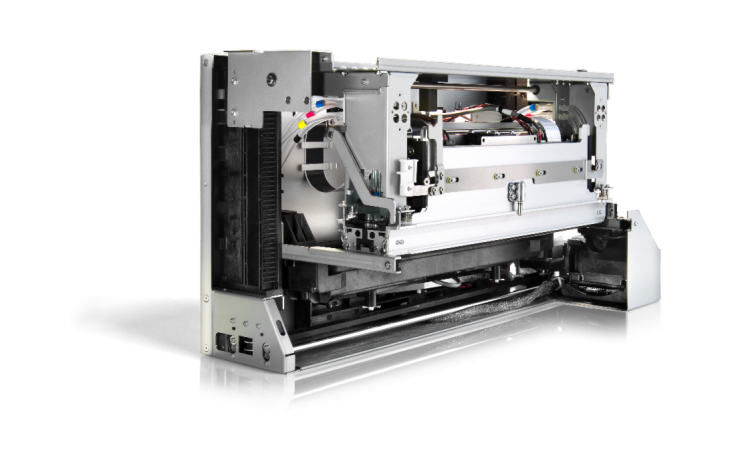

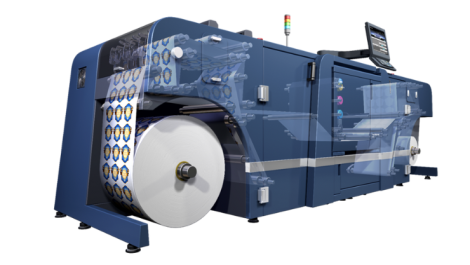

The new engine, which will use a single printhead for full colour digital inkjet production, will be available as a print module for custom integration into strategic partner solutions as well as being transitioned into Colordyne’s 2600 and 2800 Series of label presses.

‘This new single-printhead technology allows us to offer a lower cost, entry-level option to our customers interested in adding aqueous pigment print capabilities to their businesses,’ said Andy Matter, president of Colordyne. ‘As their production needs increase, they can grow into our 3600 Series AP solutions, which use a multi-printhead design. By providing scalable solutions the transition between products is seamless and offers greater business flexibility to our customers.’

‘Print markets are evolving quickly and require a partner with the vision to meet today’s challenges while planning for the future,’ added Kim Beswick, general manager of Memjet’s benchtop and mini-press division. ‘Colordyne has a proven history of using Memjet technology to create compelling solutions for their customers. They understand the print market and how to create valuable solutions that are market-leading. We are compelled by Colordyne’s vision for their DuraFlex-powered printers and committed to supporting them in achieving their next wave of success based on DuraFlex.’

DuraFlex is designed to provide longer printhead life as well as enhanced durability through greater water fastness, light fastness and rub resistance compared to other water-based inkjet technologies. Its printhead technology can print CMYK at a resolution up to 1600 x 1600dpi and speeds up to 45m/min.