Heidelberg has developed new finishing machines to facilitate adding value to short runs and digital jobs.

This includes the Digimatrix 60 C/FC for die-cutting and hot foil stamping, and Diana Go 85 folder gluer, with speeds and capabilities specifically targeted at adding value to such commercial and packaging work.

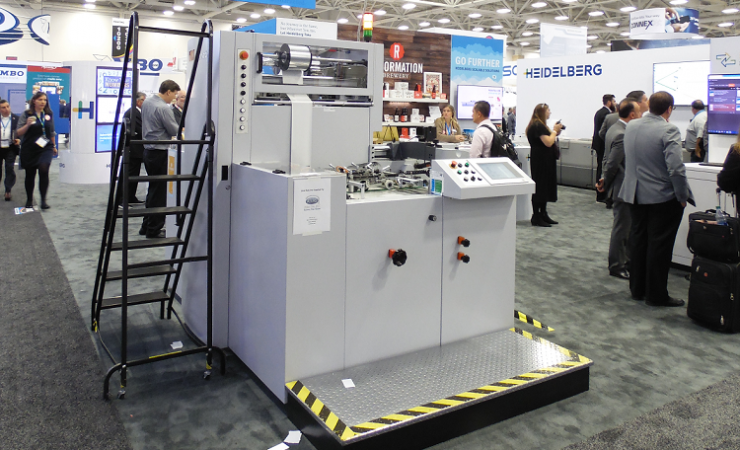

Digimatrix 60 C is a small format die-cutting and hot foil stamping machine. It has a maximum format size of 60 x 45cm and a maximum speed of 5,500 sheets per hour. The material range extends from 90-600g/sqm cardboard. Such specifications make it suitable for producing short-run die-cutting work such as presentation folders and irregular shape direct mail applications, as well as foiling and embossing folding cartons.

The FC version with foiling allows for hot foil to be applied on a variety of substrates. The foil stamping station features two servo-driven foil shafts with separate controls, foil break sensors, and air blast support to ensure good separation of the foil from the substrate. The quick-change honeycomb chase features a fast heating drive with four heating zones and a temperature range of 40-180 degrees C. The maximum foil diameter is 220mm and foil width range is 20-385mm.

Both can be equipped with the Masterwork Masterset camera-based infeed mechanism that registers each sheet individually based on the location of print mark for print-to-cut registration.

Die-cut and/or foiled jobs are then able to move onto the Diana Go 85, a compact folder gluer offering complete forming of commercial jobs and folding cartons at speeds up to 300m/min and a machine length of less than 10m. It has a wide format range, from 850mm down to 45mm, and can run folding boxboard of 200-600gsm and N/F flute corrugated board for straight-line/lock-bottom applications.

Both systems were presented to the market in North America at Printing United 2019.