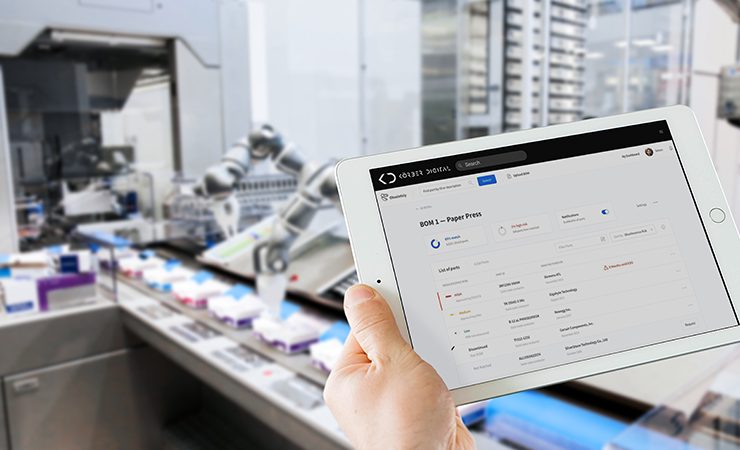

Finishing equipment manufacturer MBO Group has taken on a comprehensive database from Körber Digital in an effort to simplify the process of obsolescence management in mechanical engineering.

This has involved implementing an early warning system, built upon a smart database designed by Körber Digital that allows MBO Group to look for alternative components or suppliers in the case of a part becoming obsolete.

Developed by Körber Digital, Körber Group’s response to digital transformation, the database is intended to make it simpler for mechanical engineering companies to work together with suppliers. This reduces the amount of work involved for developers, with the system independently offering alternatives if a part has been discontinued, noted MBO.

A particular challenge in the mechanical engineering industry is noted as machines becoming increasingly reliant on electronic vendor parts. Such components have short innovation cycles, yet users require an option for replacement parts for decades to come. This means it is important for mechanical engineers to keep this development in mind when performing obsolescence management. Experts request the current delivery status of an assembly from their suppliers during the development phase and work out replacement options in the event of product change or end-of-life notifications.

‘However, these notifications are rapidly increasing, as the rate of development for electronic assemblies is so high,’ said Berthold Zinth, supply chain manager at MBO Group. ‘The amount of time and personal effort required for obsolescence management at our company has risen rapidly in the last few years. In the past, it always required more effort to respond to the situation at an early stage and to maintain an overview of everything.

‘However, this is essential for our products, which have a long service life. This was the situation we were in, which is why we started looking for a comprehensive obsolescence management digitisation solution. We found it thanks to Körber Digital.’

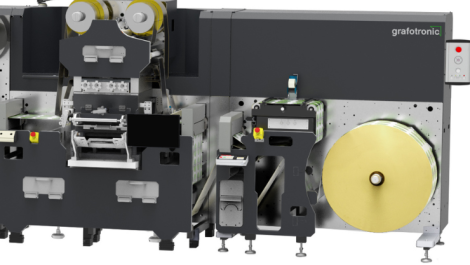

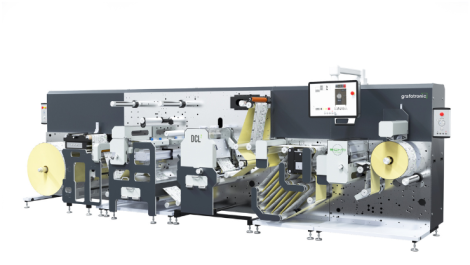

As MBO Group develops machines and automation systems intended for industrial-scale production in the print processing and pharmaceutical sectors, the machines are designed to be robust. Zinth added, ‘MBO’s top priority is to be able to deliver replacement parts when they are required – even if the machine is very old. It is just as important for MBO to identify components that may be discontinued down the line – and to do so while developing the new product.

‘Thanks to the early warning system developed by Körber Digital, MBO is now able to look for alternative components or suppliers in good time. Another advantage is that we can promptly inform our distribution partners if it appears that a part from a supplier will no longer be available in the near future. In this sense, it was essential for us to upgrade the obsolescence management.’

MBO can now streamline its entire process using the smart database, which at present contains around one million parts from suppliers. With more and more suppliers signing up and adding their data, the figure is growing all the time. Mechanical engineers can directly access parts and parts lists. The system checks the delivery and discontinuation status of the parts. If a certain part is only available for a limited period, the database will offer alternative proposals. If the delivery status changes, the database sends information to the user.

Nizar Manzli, product owner at Körber Digital, said, ‘This solution has our full support. It is available to all mechanical engineering companies. All the user has to pay is a low monthly flat-rate fee, and the first 12 months are free.

‘All in all, it enables us to turn a complicated, arduous task into a smart process where all involved can reduce the amount of work involved and be more efficient.’