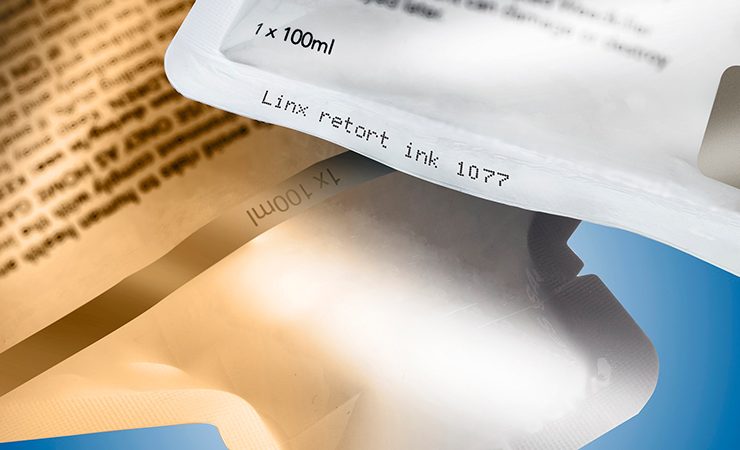

Linx Printing Technologies has introduced an ink for retort applications and specially formulated to resist moisture, colour change and transference.

The new Linx black retort ink 1077 has been formulated for consistent coding through pouch and can retort applications, where the contents are cooked in the packaging after they are coded.

Moreover, it has been designed for use in typical sterilisation and wet retort process conditions. A special formulation enables coding through a thin layer of oily film or grease. In addition, it contains components that enhance adhesion under moist and high temperature conditions, ensuring adhesion and transfer resistance, as well as durability and legibility on a range of materials after processing.

Typical applications for Linx black retort ink 1077 include a variety of food packs, such as ready meals, vegetables, beans, fruit, soup, rice, meat and fish products, and pet foods. This includes any products that are coded before a cooking process.

The ink is suitable for use on many materials including metal cans, formed aluminium, and plastic packaging such as polyester (PET) pouches.

A dye-based MEK ink, Linx black retort ink 1077 has been specifically developed for the company’s 8900 and 8800 Series continuous inkjet (CIJ) coders.