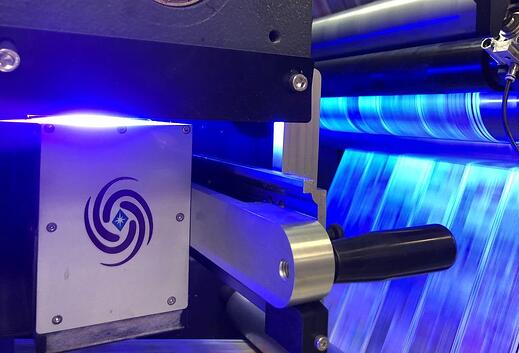

Phoseon Technology and Cyngient are working closely to develop adhesive technology that can be cured using UV LED.

Since the early 21st Century, Phoseon Technology has focused on the development of LED technology for various applications, while Cyngient has over 100 years of experience as a full-service technology provider of inks, coatings, adhesives and custom-made options for the flexographic, commercial print and durable label industries. Their on-going partnership is addressing the needs of the narrow web label industry, and beyond.

Moreover, the combination of the companies’ products is said to better meet the needs of narrow web printers using UV LED curing technology on flexographic and hybrid digital-flexo presses. This includes the family of Cyngient HYPERcure LED/UV adhesives that can be combined with Phoseon’s LED curing technology for enhanced adhesion and transfer in cold foil and lamination applications. This combination is claimed to offer up to double production speeds versus UV mercury curing and improved through cure, better cold foil transfer (3pt at 500ft/min), and stronger bonding for structural lamination adhesives on label, tube and industrial applications.

Andrew Wasserman, managing partner at Cyngient, said, ‘Technical support from Cyngient allows Phoseon to offer customers faster, more efficient leading-edge adhesive product support with predictable consistent performance.’

Read the January/February 2020 issue of Digital Labels & Packaging for more more on the curing market; register to receive the magazine here

The demand for the UV LED across ink, adhesive, and coating industries for the process of curing plays a significant role in the development of the UV LED market.