Kyocera has developed the next generation of its KJ4 inkjet printheads, with the 600dpi KJ4B-EX 600 to be the first to market later this year.

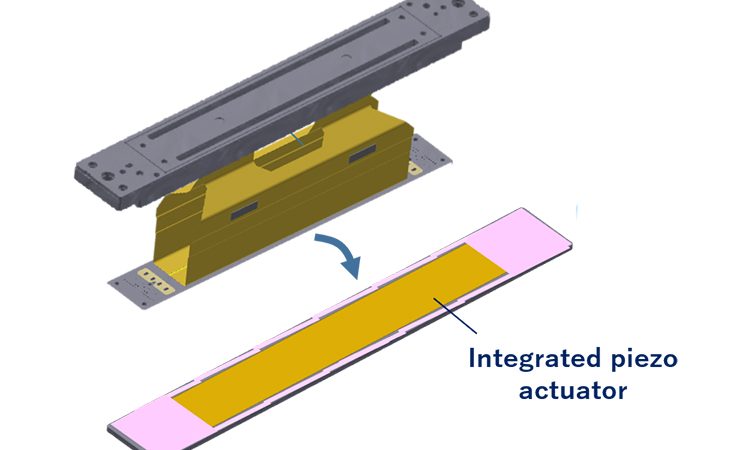

Kyocera first applied its proprietary fine ceramic technology in 2007 to create ultra-high speed piezo actuators for its record-setting KJ4 series inkjet printheads. The new KJ4 EX series builds on this legacy with a large, integrated piezo actuator and streamlined structure. This replaces multiple smaller actuators to enable more consistent image quality. The new larger actuator was created using the company’s unique material design technology for dense polycrystalline ceramic actuators, combined with its thin piezoelectric ceramic substrate manufacturing processes.

Further, integrating the piezo actuator allows greater freedom in design, resulting in a simple and robust structure.

By increasing the volume of each drop of ink ejected from the printheads and enhancing droplet ejection consistency, Kyocera noted that the new series allows high-resolution printing on a wider variety of media. An optimised ink channel design and revised structure maximises the volume of an ink drop ejected and improves ink ejection consistency. This allows the printheads and media to be separated by a greater distance without affecting droplet accuracy, ensuring high-resolution printing on a wider variety of materials, including unconventional print media. At the same time, the printhead’s durability is enhanced by improving its structural strength and rigidity.

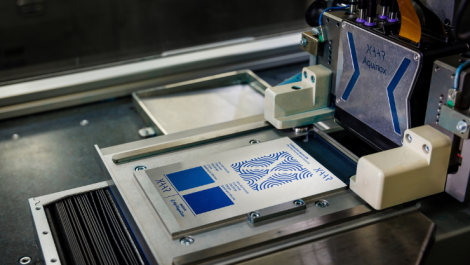

Designed to run aqueous inks, the KJ4B-EX 600 inkjet printhead offers a 600dpi at 75m/min, with a maximum droplet volume of 18pl at 30kHz driving frequency or 24pl with a 20kHz driving frequency.

Read more on the latest developments in inks and toners in the January/February issue of Digital Labels & Packaging; register here to receive all six issues in 2020, and beyond, for free