Inkjet printing specialist Industrial Inkjet (IIJ) and Global Inkjet Systems (GIS) are to further their partnership of more than a decade in order to ‘continue to meet all future challenges’.

When IIJ started development of the Colourprint 72 single pass print engine, it contacted GIS for software, printhead electronics and technical support for the essential components needed.

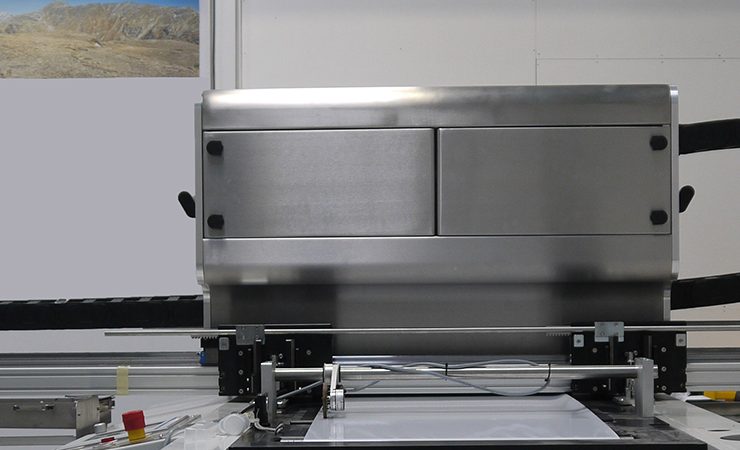

IIJ’s print engines are integrated into a wide range of applications from full colour product decoration to monochrome barcode printing. A key requirement for this equipment is a compact form factor, as this allows improved flexibility during installation. The flexibility and scalability of the GIS software and electronics product range has meant that it can be found in all IIJ products from the smallest 72mm wide print engines through to the new wide format MonoPrint 775i (pictured).

This has also resulted in IIJ and GIS establishing a collaborative relationship that allows product quality and performance requirements to be fed back, influencing feature development and product performance of software and drive electronics.

GIS’ capability for high-speed variable data printing enables is also benefiting IIJ and allowing it to meet the most demanding requirements. Paddy O’Hara, IIJ business development director, commented, ‘GIS’ variable data engine is extremely powerful. The software is much simpler and faster than trying to RIP every image for just a small area of variable text.’

The GIS variable data engine overlays the variable part of a PDF so creating a single static background that only needs to be RIP’d once. Smaller amounts of variable data can be processed faster, thereby increasing the production capacity.

This powerful variable data printing capability has allowed IIJ to target more markets, such as the garment industry, where it is able to print variable data onto clothing tags. With the increased use of RFID in the industry, being able to print human readable data that is contained in the RFID chips at high speed has really helped IIJ gain a foothold. Moreover, experience gained in this sector is transferable to others, such as high-value consumer goods.

GIS has also permitted IIJ to enjoy success in security printing, where a combination of print technologies is often used, such as digital and flexo/litho printing. This combination is often a challenge to integrate due to the speed and positioning of the overprint.

‘Being able to match not only the top speed, but also to cope with accelerations and at the same time ensuring we can overprint at the correct position is critical for our print engines,’ explained Mr O’Hara. ‘By using the GIS software, we no longer see these issues when integrating onto existing lines due to its flexibility. Different systems have different inputs both in terms of electrical and software requirements, and the ability to easily change resolutions, etc., allows the GIS software to be tailored not only to the line, but also for different job types.’

A further challenge is seen when overprinting is done onto a product that has been part processed prior to the variable data being applied. It is important that the variable information is overprinted in the correct position on the substrate, such as in the printing of information onto ID cards and passports. In such cases, the pages or cards have the background image printed using traditional offset methods, and then sheets are pre-cut prior to the variable information being applied. This two-step process can introduce tolerance errors where the substrate has been cut, with potential for the data to be printed in the wrong place. Being able to ensure that the this does not happen is made possible by the GIS dynamic XY positioning software. This identifies where on the substrate data needs to be printed and shifts the image by the required distance, so ensuring that an individual photo or address appears in the correct location.

‘Without doubt, GIS has enabled IIJ to grow,’ said Mr O’Hara, a situation that is set to continue as the combination of the two company’s technologies, product flexibility, and effective feedback loop sets IIJ and GIS up to ‘continue to meet all future challenges’.