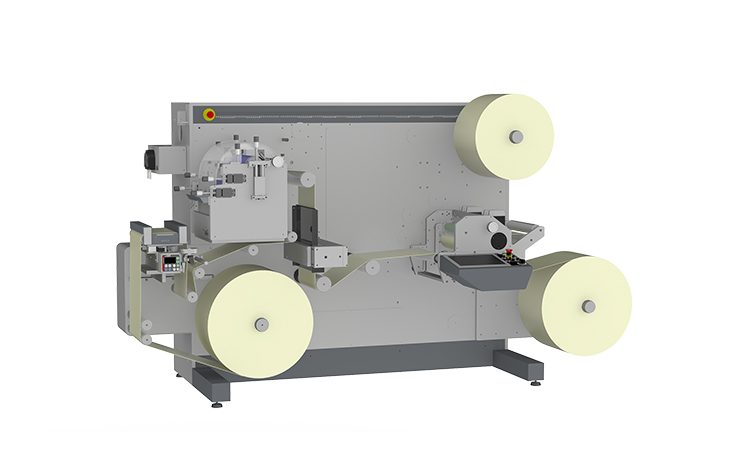

Danish finishing specialist Grafisk Maskinfabrik (GM) has developed a new coater for adding a high-quality coating to printed products.

Principally developed with processing of photo papers in mind, the GM Photo Coater can also be used to finish labels, stickers and other roll-fed products.

It has been designed to add a high-quality UV coating to protect and enhance the images. It features a UV flexo varnish station, which can be equipped with a sensor to offer spot varnish and super gloss embellishment for superior quality. UV curing is achieved with the use of a GEW E2C UV lamp with large reflector.

GM noted that a UV coating guarantees that professional quality photos, printed on paper using silver halide or digital technology, are protected against the effects of UV light, abrasion, fingerprints and other damaging actions. Providing the required gloss level, the UV coating also preserves the appearance of images and enriches colour, as well as guarding them from discolouration and fading.

The GM Photo Coater has a compact footprint and features helical gears to ensure minimum vibration, while the drive train is completely servo-driven offering low maintenance tension control and excellent registration. The flexo coating station can be accurately controlled to reduce the cost of varnish. Optional modules for lamination, cold foiling and slitting can be fitted, as well as an additional 600mm wide rewinder.

The GM SmartCrush system provides ultra-quick set knives system for fast and precise setting of each crush knife, including on-the-fly setting.

The GM Photo Coater can run either offline or inline with photobook manufacturing equipment and digital printing presses. An optional buffer can synchronise the speed between the press and the coater, with a GM Mini Buffer allowing switching between inline and offline mode.

Read more about finishing and embellishment in the March/April issue of Digital Labels & Packaging; register here to receive the magazine, for free