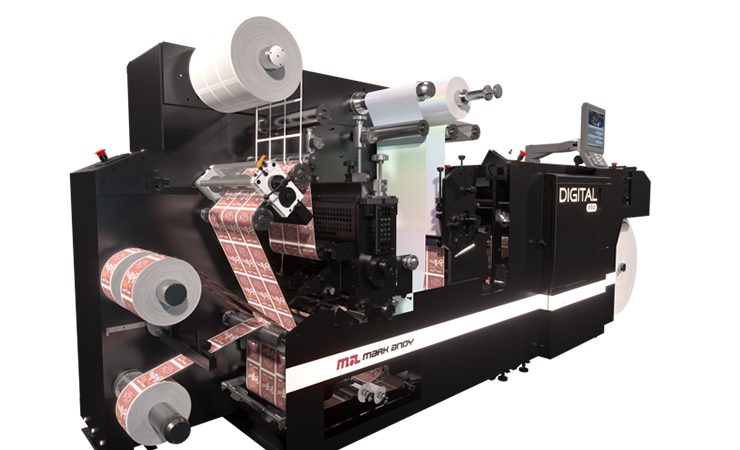

North Carolina’s Subtle Impressions has upgraded its Mark Andy Digital One with the supplier’s Digital Pro engine upgrade.

Subtle Impressions installed a Mark Andy Digital One in January 2019 to fulfil the need for a digital label printing option, and provide an alternative to the longer lead times typical with flexographic production.

After a year of production with the Mark Andy Digital One, Chris Brown, co-owner of Subtle Impressions, noted, ‘All of the existing business that prompted us to buy the Digital One initially, we have absorbed and done business above and beyond that. It’s been a great stop gap for us when our flexo press has been too busy.’

After experiencing success with the Digital One first-hand, Brown learned of the engine upgrade for the press via the Mark Andy Digital Pro portfolio. This includes the two press models, Digital Pro 1 and Digital Pro 3, and an engine upgrade to enhance existing Digital One customers’ machines. Engine upgrade benefits include higher speeds, a lower cost to print, and life expectancy extensions of digital assets. Specifically, the engine upgrade enables speeds of 24m/min, a 70% increase over its predecessor, as well as a 30% lower cost to print. Lower cost to print stems from toner consumption efficiencies of the new engine as well as higher yield on certain consumables native to the new platform.

When weighing a new press acquisition against an upgrade to his Digital One, ultimately it came down to speed for Mr Brown. ‘We looked at a few other digital machines that were just way too slow. The new digital print engine is great from a quality standpoint, does not take up additional space on our floor, and has increased our capacity tremendously.’

Melanie Hunt, press operator at Subtle Impressions, exampled, ‘We have a customer who typically runs 14,000 labels that are three across. With the old engine I’d have to run in three batches because of the recalibration and diameter of the roll. Now I can get that produced in two batches. Not only does that have double the speed because it runs twice as fast, but it probably saves 20 minutes of changeover time between stopping and changing out material and laminate between batches.’

Mr Brown continued, ‘What’s nice about Mark Andy digital is that it is all inline. Faster throughput, less set up and clean up times, and a bridge transferable skillset and training of the existing workforce are all benefits we see in digital hybrid technology.’