Actega is significantly expanding its production capacities for water-based and UV overprint varnishes (OPVs), which will see global production output increase to more than 150,000 tons per year.

Andreas Gipp, a senior vice president at Actega, said, ‘Actega consists of 11 companies with worldwide production facilities and sales offices. Due to our production sites in Europe, North and South America, as well as in China, we can not only better serve internationally operating printing groups and be closer to our customers, but also proactively support them in their growth.’

Around €2 million has been invested in a new integrated site in Brazil, with production and warehousing occupying most of the 12,000sqm facility with new high efficiency equipment installed to produce OPVs.

Andrei Sotkeviciene, managing director at Actega in Brazil, commented, ‘Research and development activities will take place in an ultra-modern, 500sqm research laboratory set up for this purpose.’

Actega has also recorded a significant increase in production capacities, especially for UV coatings, due to the integration of Schmid Rhyner. This company, based in Adliswil, Switzerland, specialises in products for print finishing and digital printing.

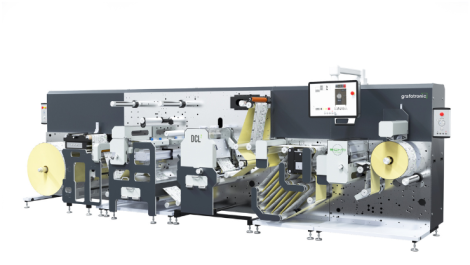

Actega is to continue to focus strongly on new technologies and products, including for digital printing and digital varnishing. As early as 2016, competence and technology centres for digital printing were established at the company’s Lehrte site near Hannover, Germany and the Cinnaminson facility in New Jersey, US. Here not only all R&D activities are bundled, but also inks, primers and overprint varnishes required for the use of digital printing technologies are provided. Moreover, Actega offers – based on the diVar technology developed and patented by Schmid Rhyner – a wide range of digital coatings suitable for both FCM applications and general printing on sheet-and web-fed printing assets.

Another example of the focus on new technologies is EcoLeaf, which enables metallisation without foil and thus improves the sustainability of all related processes.

Safety and sustainability are further components of Actega’s R&D and NPD roadmap, as shown with ACTGreen as a portfolio of water-based coatings mainly for folding cartons and labels applications. All matte and gloss coatings have been formulated based on renewable or recycled raw materials.

Mr Gipp said, ‘Already now we achieve more than 25% of our turnover with new products, and R&D investment represents 10% of our sales turnover. It is in our interest to conduct intensive research and to continuously improve products. Thus, we are currently working on a next generation of barrier coatings, enabled by novel aqueous thermoplastic elastomer dispersions of the Yunico technology, which are free from emulsifiers and solvents.’

Actega is also working in line with the objectives of parent, Altana Group, to reduce its carbon dioxide emissions from production and energy procurement to zero worldwide by 2025, in order to protect the climate and the environment.

Read more about substrate treatment and preparation, and finishing and embellishment in the March/April issue of Digital Labels & Packaging, which can be read online here