Canadian digital printer Premier Markings has installed a Xeikon PX3000 UV inkjet digital label press, complementing its dry toner printing expertise.

Premier Markings started operations in 2008, with founder Gary Moody opting to launch as a digital printing company in order to allow the business to more easily manufacture labels in-house, as well as respond to evolving market trends. It produces a range of different labels, including craft beer, nutraceutical labels, labels for the cannabis industry and, lately, due to COVID-19, a lot of hand sanitiser labels.

The company started with a low volume tabletop label printer, suited for very short-run orders of 500 pieces, although it soon became clear that a productive high-quality label printing press was needed to make the company a success. After researching the supplier market thoroughly, Premier Markings decided to buy a Xeikon 3030 in 2013. To further increase productivity, Premier Markings added a second Xeikon 3030 press, with one of these two later upgraded to the 3300 model, essentially doubling its capacity.

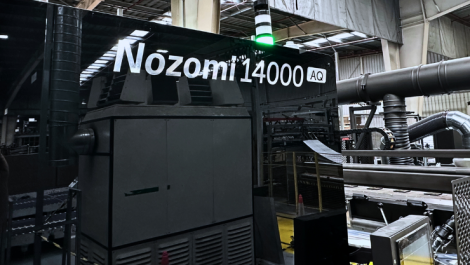

In January 2020, the Xeikon PX3000 UV inkjet machine replaced the remaining Xeikon 3030. Mr Moody had been considering investing in an inkjet press for two years, with the speed of inkjet appealing to him, coupled with a better than expected print quality.

‘It was a tough decision to choose what type of inkjet press to go for as there are alternatives to the PX3000 from Xeikon,’ commented Mr Moody. ‘Eventually, an impressive demo at the Xeikon Chicago Innovation Center as well as knowing the certainty of having the very reliable Xeikon team at hand made the difference, and we opted for the Xeikon PX3000. Furthermore, the fact that the PX3000 uses the Xeikon X-800 as digital front-end was a big factor too. It is an invaluable tool in our business to make the most of digital printing and the fact that all our presses are driven by that same front-end is a big advantage.’

Mr Moody had thought that inkjet was the future for everything, but Premier Markings learnt it is not that simple, with both dry toner and UV inkjet having pros and cons. Dry toner’s benefits in terms of food-safety compliance are most often noted, with the durability of labels printed using UV inkjet likewise highlighted. In Premier Markings’ short experience, the dry toner press is a described as a ‘very consistent machine, but it requires more maintenance’. The inkjet press, however, ‘needs less maintenance but is more vulnerable’, according to Mr Moody. Substrate suitability is another consideration for Premier Markings, with stock that has a structured surface and matte BOPP more suited to the dry toner digital printing process. Chrome substrates based on PP run better on the inkjet press.

Mr Moody said, ‘Over the years we have constantly grown double digit on a yearly basis. The first years we grew over 30% a year. Our business model is delivering a service that our customers need, we listen to and deliver what our customers require, most labels are delivered in two to three working days.’

Addressing the decision to launch and continue to invest in digital, Mr Moody explained, ‘A typical digital job is rotating warning labels; a product that has different warning messages or pictures. Different pieces of the same product on the shelf need to show different warnings. I don’t see how you could possibly print that on a flexo press.’

He continued, ‘We ran a job of 1,000,000 labels on the Panther; my flexo printer colleague could not realise this job in three days, so we did it on the UV inkjet press.

‘Two years ago, this flexo label printer produced more labels for us than Premier Markings printed for his customers. Last year that changed. He knocks on our door to print jobs digitally quite frequently, while we need his flexo capability less and less. This evolution will only continue in the years to come. We have the flexibility to run all sorts of labels in different quantities in much less time.’