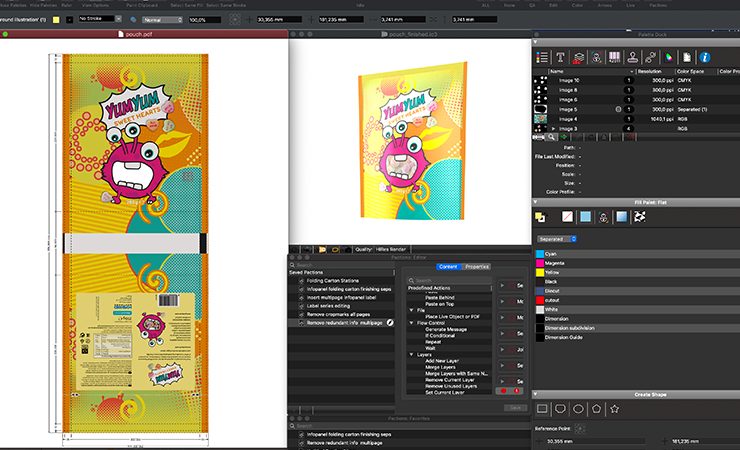

Over the last 18 months, Brentwood, UK-based trade printer Baker Labels has transitioned its pre-press studio department to use Hybrid Software’s systems, including Packz, Proofscope and Cloudflow.

As an early adopter of digital print, in 2006 Baker Labels was one of the first companies in the UK to install HP Indigo print technology. Since then, the printer has made continual investment in its digital print capabilities, culminating in their current configuration of three HP Indigo WS6900s, an HP Indigo 20000, and two Screen Truepress L350UV+LM inkjet presses. It also operates a Nilpeter FB3 flexographic press.

Since moving production to a state-of-the art facility in Brentwood in 2011, Baker Labels has seen a rapid expansion, including the addition of the flexible packaging division, BakPac, in early 2020. The growth created a need for additional processing power at the front end and was the driving force behind looking at Hybrid as a system to help alleviate potential production bottlenecks.

Jamie Godson, technical manager at Baker Labels, commented, ‘My initial impression of Hybrid was that they were agile, innovative, and the type of company that would work as a partner rather than just another supplier.

‘The decision to invest in the Hybrid Software system was not taken lightly but it was concluded that this was the front end system that would not only help cement our position as one of the top label printers within the UK but also help drive the mantra of ‘continuous improvement’ for the foreseeable future.’

Mr Godson continued, ‘Due to our trade nature we have to be able to work with every type of artwork imaginable. Not only do we need the capability of processing the different files, we have to be able to do it fast, very fast. Initially the Hybrid software was brought in to increase our processing speed, obviously after that we opened up the full potential of what the Hybrid products could offer so we developed and continue to develop them exponentially.

‘Successful integration of Hybrid has not only improved speed to press, it has given us another platform which enables us to cover as many bases as possible regarding the files that we receive from our customers. There are many efficiency improvements that we have made, from using Hybrid’s VDP solution to simple rules that have been applied to update multiple files in the quickest time possible. I won’t give away all of our secrets but the software, coupled with the support that Hybrid has given, have had a major impact in improving our daily working practices. As technical manager, pushing the boundaries of what can be achieved with the Hybrid products is an unfinishable project that will always sit in the top three of my to do list.’

Baker Labels entered the project having substantial experience of another system that had been used for the previous eight years. However, more complicated artwork and an ever-increasing average number of SKUs per job year-on-year necessitated more power. Further, in receiving artwork from all over the UK print industry, Baker Labels identified that more and more Packz files were being supplied. Although already fully up to speed with the latest Adobe suite offerings, Baker Labels acknowledged the advantage that a high-end PDF editor would give and have regularly seen instances where Packz has saved large amounts of time in file preparation.

Currently Packz, Proofscope and Cloudflow are installed within the seven-strong Baker Labels pre-press studio, with plans to have seats established on the shop floor both in the labels and flexible packaging production environments.

Greg Heather, UK sales manager at Hybrid Software, said, ‘We are very pleased to be part of the continual improvement of automation at Baker Labels. The close relationship we have developed between the two companies has seen Bakers create processes that have successfully driven efficiency increases and cost savings using our technologies.’

Baker Labels commercial manager Jamie Doogan added, ‘The fit between the two companies was right. There are a lot of similarities in our ethics and vision. We needed a partner that was going to understand our business and how we were developing as a company and could ensure we had a system that was future proofed. By working closely together I feel we have achieved this.’