Grafisk Maskinfabrik (GM) has introduced a new laser finishing unit, LC350, designed with current market trends and future requirements of the label industry in mind.

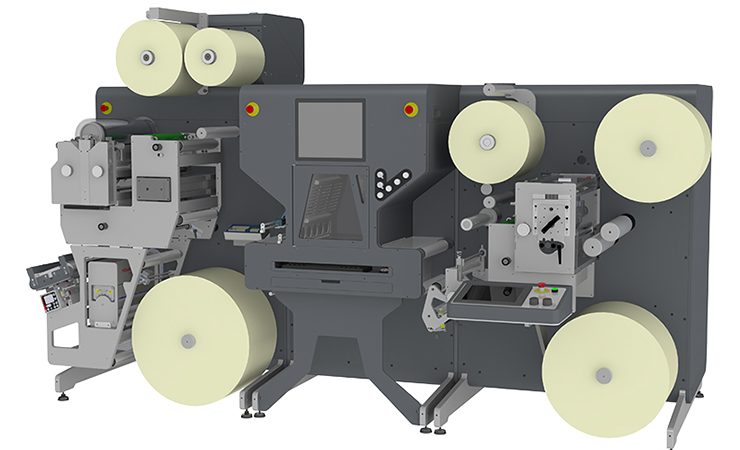

LC350 is a compact laser finishing unit from GM featuring state-of-the-art laser cutting technology to replace traditional die-cutting and its associated costs in tooling and tooling storage. It is described as a ‘compact, cost-effective’ fully digital laser finishing machine that offers complex label finishing with superior cut quality, varnishing and spot varnishing with SmartFlexo semi-rotary module, as well as lamination, cold foil, web slitting and dual rewind. Other options include corona treater, SmartSlit slitting module with automatic knife positioning system, and a barcode reader for fast job change or quick recall of existing jobs. LC350 is available in 250 and 350W versions. It features a new electronic platform and a larger touchscreen for easy operation.

LC350 can be supplied with full connectivity through GM’s VPN Gateway option for remote diagnostics, service and support using a secure internet connection. This establishes access through the firewall of the existing wired network infrastructure to provide remote access for on-demand, real-time servicing.

The LC350 joins GM’s expanding portfolio of converting lines that are capable of producing labels in a web width of 350mm.

By combining the latest laser cutting technology with a wider web width, ‘the LC350 increases productivity and meets the demand for faster delivery, especially of short run print jobs,’ according to GM CEO Uffe Nielsen. ‘Laser cutting has come a long way since it was first introduced in label converting, and it now offers an excellent and sophisticated alternative to conventional die-cutting, particularly for digital labels.’

The LC350 works either offline or inline with all major digital presses. The laser module on its own can also be used in a hybrid configuration and be added for example to the GM DC350 converting line.