Inkjet digital printing is set to be one of the contributing factors to the corrugated packaging market topping $200 billion by 2025, according to Smithers.

Despite the impact of Covid-19, Smithers’ latest report, The Future of Global Corrugated Board Packaging to 2025, forecasts that global corrugated board will increase at a compound annual growth rate (CAGR) of 3.8% across 2020-2025 to reach $205.7 billion. The volume of board consumed worldwide will increase at a slightly slower rate to reach 193.2 million tonnes in that year.

The Smithers study tracks micro and macro trends in this industry for 2015-2025. This is segmented across for six corrugated grades – unbleached kraftliner (UBKL), white-top kraftliner (WTKL), unbleached testliner (UBTL), white-top testliner (WTTL), semi-chemical fluting (SCF), waste-based fluting (WBF); 15 end-use applications; and 63 countries and world regions.

The Covid-19 pandemic will see a marked impact on corrugated consumption in certain sectors and regions, especially those worst affected by the virus. In terms of end uses, food shipments will be least affected while other consumer items will see a more significant drop. These will be mitigated in developed regions by the strong increase in e-commerce as stay-at-home consumers undertake more online shopping. Several board converters have developed e-commerce specific delivery designs to capitalise on this, accentuating what the industry has already identified as a key growth segment.

In the longer term, Smithers analysis identifies the following business trends as shaping the future of corrugated board packaging:

- Recycling and sustainability, which will remain a key concern for converters and brand owners, although oversupply of materials is liable to generate new price pressures;

- New coating technologies, including bio-based polymers, will help improve the recyclability of coated corrugated grades;

- Demand for finer flute grades, required for high-quality printed cases and as alternatives to folding cartons;

- Further pressure for light weighting of corrugated designs, which will negatively impact volume sales as less fibre delivers an equivalent required performance;

- E-commerce, which will continue to expand, even once lockdown (shelter-in-place) orders have been revoked, and will generate new need for white-top liner that can receive high-quality print graphics;

- Dimensional weighing in packaging, and the focus on minimising extraneous protective components will slow some of the expanded use of corrugated in direct-to-consumer and e-commerce shipping;

- More use of retail-ready packaging formats, as more modern retailing expands into developing markets in Asia and elsewhere;

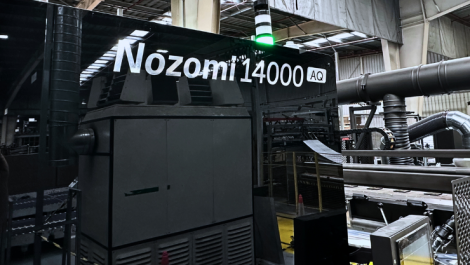

- Digital (inkjet) printing will increase with overall demand for better quality substrates, and expand the options for packaging printers in both standard and RRP corrugated formats;

- Industry consolidation will lead to greater concentration of capacities and more uniformity for users.

A number of players have entered the digital corrugated package printing market this year, notably Domino, Screen and Xeikon.

Register here to receive the next issue of Digital Labels & Packaging, which will be published alongside the publication’s annual inkjet supplement