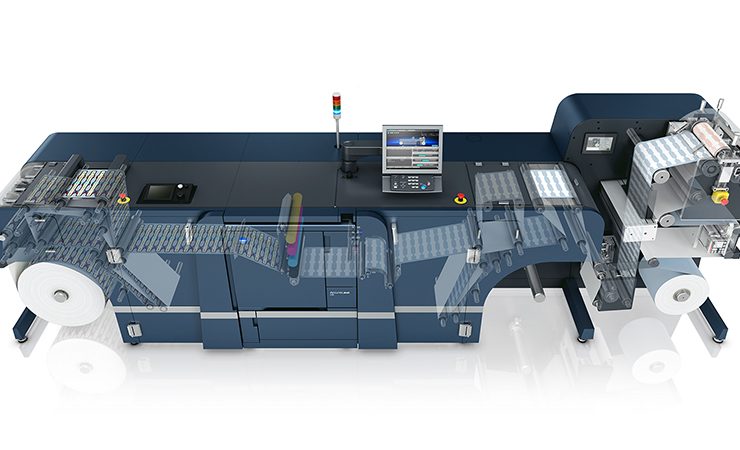

Konica Minolta has introduced an optional flexo printing unit for its AccurioLabel presses, designed to enable inline production of white and other colours.

The flexo printing unit comprises an unwinder, web guide, a complete flexo printing station, UV curing system, an output nip and a touch control panel. The AccurioLabel flexo printing unit uses standard flexo inks. In combination with the sensor kit as part of an already available optional overprinting unit, the flexo printing unit provides registered inline overprinting of white or any other colour, which opens up a wider range of print applications such as printing on clear substrates.

Developed with Konica Minolta’s manufacturing partner in Europe, Danish company Grafisk Maskinfabrik (GM), the flexo printing unit can be retrofitted to the Konica Minolta AccurioLabel 190 and 230 toner digital label presses.

It is targeted at label converters seeking a hybrid option to complement high-end digital printing systems.

Edoardo Cotichini, team manager, Industrial Printing at Konica Minolta Business Solutions Europe, said, ‘The label printing market is considered as one of the main market segments that will grow in the future. And this year alone, almost half of the narrow web label installations will be digital.

‘The introduction of our optional flexo printing unit is a new way of looking at hybrid technology. It’s been driven by market demands and we are looking forward to further growing our market share in labels – a market we only entered five years ago but have now sold over 500 label machines – and industrial print in general. Working closely with our customers in a partnership approach, we will also help them to rethink what’s possible. The march of digital production is unstoppable.’