Bar Graphic Machinery (BGM) has received four orders from the UK and Europe in recent weeks for its Digiflex digital finishing line.

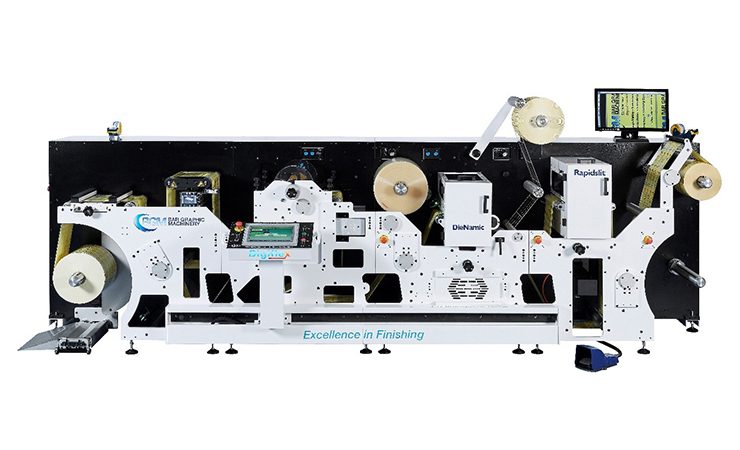

The BGM Elite Digiflex is a full servo re-register flexographic die-cutting converting and finishing system. It has been developed to print, apply additional coatings, semi-rotary die-cut at DieNamic speeds of up to 110m/min, slit, and rewind all in register in one or multiple passes. Speeds of up to 160m/min can also be achieved.

A modular design enables customers to configure the specification of the machine to their exact requirements and futureproofs the machine for later configuration adaptations, if required. All four of the latest orders – three to customers in the UK and one into Europe – have been ordered with individual configurations. All will be supplied with BGM’s latest re-register flexographic print station and semi-rotary die-cutting station. Both incorporate a laser function that enables the operator to pre-position the print cylinder or die shim in register to the pre-printed media, enabling pre-registration to the print and minimising waste and operator downtime. Furthermore, the machines will be fitted with BGM’s automatic digital knife box that automates the setting of the slitting blades through the HMI touchscreen. Rapidslit takes slitting further into automation by eliminating operator error and inconsistency, providing precise setting of the blades within seconds not minutes.

Order configurations will also include options such as a re-register insetter for the process of peel and reveal, cold foiling, lamination, festoon for continuous workflow, semi-automatic turret with splice and tail applier, variable repeat sheeting module. Additional auxiliary options such as corona and web cleaning systems have also been ordered.

BGM managing director Annemarie Rhodes said, ‘We are truly delighted with the amount of interest the new Digiflex is generating. Four machine sales of a new product in six weeks is very promising.’