Coding and marking specialist Linx Printing Technologies has launched Linx Yellow bottling ink 1088, a fast-drying yellow bottling ink to meet the demands of customers who require a high contrast code on dark coloured bottles.

Such bottles are usually returned from the marketplace and cleaned in a caustic wash process, typically used for returnable bottles, before refilling and coding. Linx’s new fast-drying ink has been formulated to provide excellent adhesion on glass and to withstand the manufacturing process, packaging and condensation.

The ink is claimed to deliver clear, legible codes onto glass and maintain adhesion in cold-room condensation conditions. I is also suitable for a weak caustic wash process to remove codes on steel, nylon and PET kegs and barrels.

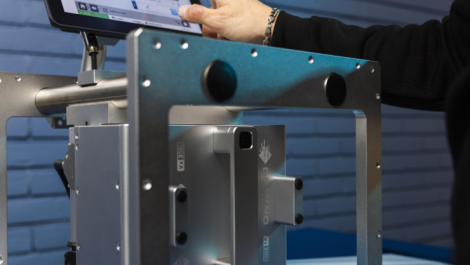

The new Linx yellow bottling ink 1088 has been specifically developed for the company’s 8900 and 8800 Series continuous inkjet (CIJ) coders. It is a pigmented ink.

Simon Millett, inks product manager at Linx Printing Technologies, said, ‘Due to the ink’s fast-dry properties, the printed code resists refrigerator storage and immersion in water, making it ideal for beverage applications like beer and soft drinks.

‘In addition to providing a high contrast code on dark brown and green bottles, the new Linx Yellow bottling ink 1088 is also suitable when a more unobtrusive code is needed on clear glass bottles.’