Chinese OEM King Tau has developed a new industrial-grade print engine, Magic Cube, which incorporates Xaar’s advanced printhead technologies.

As a pioneer in the ceramics and graphic sectors, Guangzhou-based King Tau is an equipment manufacturer with more than 20 years of experience in the development of options for many different industrial inkjet applications. This includes systems for digital printing of corrugated boards and packaging, as well as for the decoration of glass and ceramics.

Its new Magic Cube utilises Xaar’s TF and High Laydown (HL) technologies for ‘significant’ performance improvements for industrial inkjet printing. TF technology allows fluids to flow directly past the back of the printhead nozzle at very high flow rates. This prevents the nozzle from drying out, increasing its open time, and ensuring that the printhead is continuously primed for trouble-free start-up, even after periods of non-use. HL enables the printing of textured effects onto flat surfaces up to 80microns in thickness on every pass. This provides reliability and higher productivity to Magic Cube, according to Xaar.

The partnership with Xaar for the launch of the Magic Cube print engine is noted as having, ‘further enhanced the company’s reputation for high quality and performance inkjet printer manufacturing.’

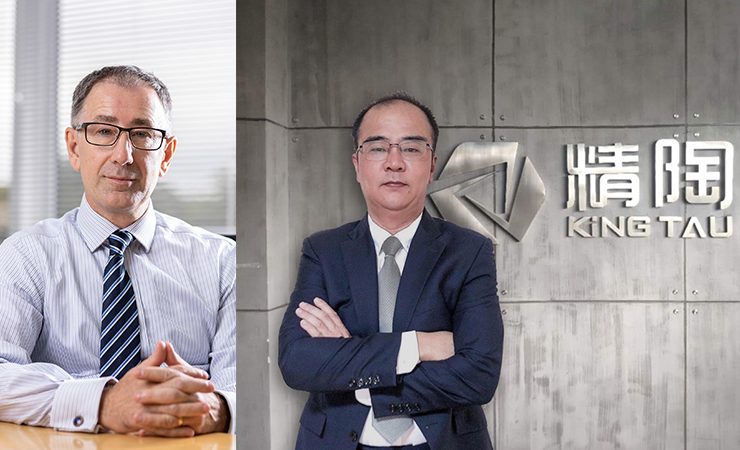

Mr Tong, managing director at King Tau, said, ‘Our trust in the technical reliability and durable performance of Xaar’s printhead technology were key to our working together. In addition, Xaar’s unique specialist technologies deliver real value for our customers and differentiate our brand from competitive products.’

For Xaar the tie-up with King Tau underlines its commitment to developing global partnerships and collaborative projects.

Xaar CEO John Mills commented, ‘We are delighted to be working with an industry leader such as King Tau and welcome the opportunity to provide our products and technologies in China. Through our partnership we see great potential in delivering the quality, performance and reliability that the Chinese market demands.’

Read more about developments in printheads in e March/April issue of Digital Labels & Packaging; register here to receive the magazine, for free