Tomra Recycling has confirmed V-Shapes’ single-dose sachets as being constructed of polypropylene and easily detected in the waste stream for proper sorting.

V-Shapes is a supplier of vertically integrated products and services for convenient, hygienic and sustainable single-dose packaging. Tomra Recycling is a designer of customised sorting and recycling systems. V-Shapes sachets are constructed with material from a variety of sources, including V-Shapes in-house-developed materials, as well as substrate provided by Sihl that is specifically designed for recyclability and suitable for use with inkjet digital printing. The result is V-Shapes recyclable material that is also compatible with Sihl Artysio recyclable functional flexible packaging films for aqueous inkjet printing, and providing multiple choices for sachet configuration. V-Shapes, Sihl and TrojanLabel have recently partnered to promote such a system for inline converting and filling of single-dose, recyclable sachets that have been decorated using digital print. These recyclable single-portion sachets can be printed on the top and/or bottom sides in multiple languages, with customised brand messaging and use instructions.

The specific sachet materials tested by Tomra were constructed of a V-Shapes developed semi-rigid material for use on the bottom of the sachet and a V-Shapes developed flexible polypropylene monopolymer for use on the top layer, which includes a thin inner liner of aluminium oxide to establish a barrier to prevent migration of contaminants into the packaged product. Pre-cut sheets, rather than assembled products, were used in the verification process.

In addition to verification by Tomra of the sachets’ detectability, the independent auditing company Interseroh has confirmed ‘excellent recyclability’ of the V-Shapes ‘Made for Recycling’ polypropylene packaging used to create V-Shapes sachets.

Jesper Gustavsson, business development and founding Partner at V-Shapes, said, ‘We offer a wide range of substrate types for our single-dose sachets, depending on customer needs and the product type being filled. We are especially pleased to be able to offer our customers a recyclable polypropylene sachet based on materials recently developed by V-Shapes which have been shown to have excellent industrial recyclability by a number of certifying organisations, including most recently sorting verification by Tomra and certification of the Sihl media by Interseroh.’

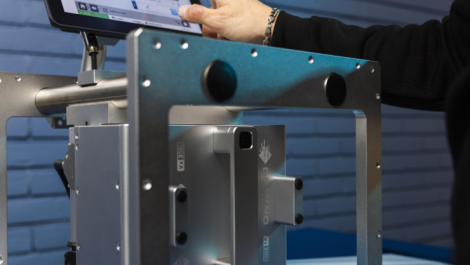

Charlotte Glassneck, plastics applications manager at Tomra, said, ‘We were satisfied with the detectability of V-Shapes sachets constructed from V-Shapes-developed monopolymer polypropylene and the ability for the sachets to be accurately detected in the waste stream using our near infrared (NIR) light detection system. Even the smallest V-Shapes polypropylene sachets, which are available as small as 40 x 50mm and 40 x 80mm, are detectable as they are sorted in the waste stream using our detection equipment and can be accurately sorted in the industrial recycling process.’

One customer to have already adopted V-Shapes sachets is Orlandi, Inc, a specialist in fragrance and cosmetic sampling. The company’s senior vice president, Sven Dobler, said, ‘For purposes of recycling, the V-Shapes sachets are considered rigid materials; industrial recycling centres have difficulty recycling flexible materials. We believe the ability to guarantee the V-Shapes 100% polypropylene sachets as detectable per the Tomra tests will be a significant boost to our business and drive conversion from flexible single-unit packaging to the V-Shapes solution. The concern about waste and consumer consciousness about sustainability are barriers to the adoption of conventional flexible single-unit packaging, and our high-end cosmetics brands are eager to include this packaging concept in their offering for a more circular economy approach.’

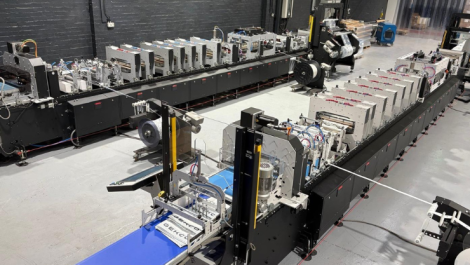

V-Shapes CEO Christian Burattini concluded, ‘Especially during the Covid-19 pandemic, brands, retailers and operators of large-audience venues such as sports arenas, airports and theme parks have expressed a growing interest in a more sustainable, hygienic and convenient way to dispense products in precise single-dose measures. These sachets, constructed of V-Shapes developed monopolymer polypropylene ‘designed for recycling’ substrate, combined with the efficiency and cost savings associated with our vertically integrated Alpha and Prime converting/filling units, offer a revolutionary way of meeting those needs.’

Read more about developments in sustainable packaging in the March/April 2021 issue of Digital Labels & Packaging; register here to receive the magazine