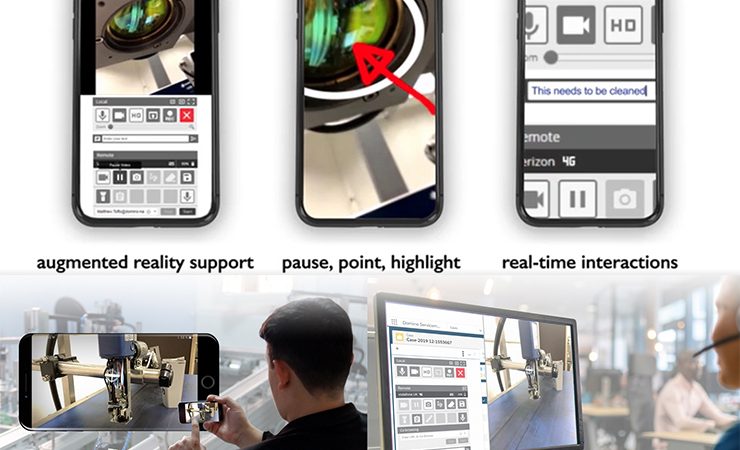

Domino has developed a new augmented reality (AR) tool, SafeGuard AR, to provide real-time, remote visual support for customers around the world.

Though already in development at the time, the Covid-19 pandemic accelerated both the completion of the SafeGuard AR application and the full programme of testing by customers. The virtual aspect of the application has proven to be, ‘particularly useful in overcoming limitations on site visits by service engineers during the global lockdown,’ noted the company. Following this success, Domino is now able to offer the service to customers in all regions.

Domino joins a growing number of equipment manufacturers to offer remote maintenance and support services, virtually, including A B Graphic and its remote assistance tool, VERA.

Domino noted that collaborating with customers in this way also allows service engineers to gain a better understanding of a problem than afforded by traditional phone support. When possible, a customer can be guided to safely implement a fix themselves, or, in cases necessitating a site visit, an engineer can be dispatched with a thorough understanding of the issue and equipped with all necessary materials to resolve issues. As such, SafeGuard AR is claimed to help increase the first-time fix rate and ‘dramatically’ decrease case resolution time. This has proven particularly relevant to those using its technologies for coding and marking applications, which continued to account for the bulk of Domino’s customer base.

Eddie Storan, head of global service at Domino, explained, ‘Uptime and overall equipment efficiency are of the utmost importance to our customers; when unplanned downtime is due to coding and marking equipment, it can be both costly and frustrating for them.

‘As coding typically sits towards the end of the production line, a faulty system can have a huge impact through wasted stock and rework, with the added commercial and brand risk of product recalls and punitive fines.’

Saverio Barbero Lodigiani, group service project manager at Domino, added, ‘We realised the value of AR in enabling our customers to manage both simple and complex cases, reducing the need for in-house skills and competencies. With SafeGuard AR, our experts can work with our customers, OEM partners or even Domino service engineers to manage complex installations, check line performance, and, crucially, identify and fix problems with machinery as and when they arise.’

Mr Storan continued, ‘At Domino, we are committed to continuously improving our industry-leading expertise to provide fast and efficient support to our customers. This is dependent not just on our products and solutions, but also on the quality and technical capability of our global service organisation. With SafeGuard AR in conjunction with Domino Cloud, we are able to offer a higher level of support which in turn provides additional customer value in terms of reduced downtime and improved production efficiency.’