HP has introduced a series of innovations for its PageWide corrugated digital press portfolio, intended to help drive scaled and profitable production of digitally printed packaging applications.

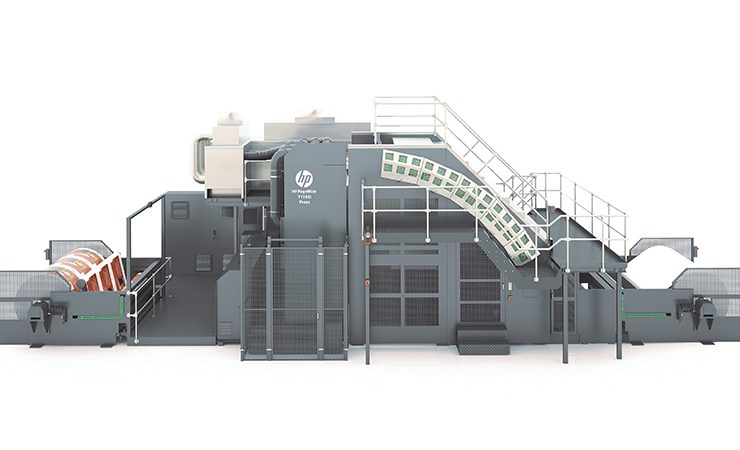

To be formally launched at SuperCorrExpo next week, which runs 8-12 August in Orlando, Florida, the developments include the HP PageWide T1195i for pre-print corrugated printing and featuring new printhead technology. These new thermal inkjet printheads on the 110in-wide HP PageWide T1195i are designed to deliver more robust and economical production for roll-fed presses, to drive mainstream production and enable converters to move more jobs from flexo pre-print and litholam, to digital. The printhead technology incorporates thermal control features to enhance pre-print system performance and help reduce operational costs, while delivering consistent high quality at high speeds. Using these printheads, the press features improved paper handling capabilities to support a wider range of liners and applications.

Georgia-Pacific’s Hummingbird division will be the first to deploy the new HP PageWide T1195i digital press at a new site in Phoenix, Arizona due to open later this year.

Robert Seay, vice president, digital print solutions at Georgia-Pacific, noted, ‘With the purchase of the second HP PageWide T1100 series press for installation in Arizona to better serve the West Coast, Georgia-Pacific’s Hummingbird operation will be able to scale its digital print solutions for packaging to offer customers greater flexibility nationwide and meet the increasing demand for shorter turnaround time.

‘The new printhead technology on the HP PageWide T1195i digital press is expected to further enhance the productive capacity and reduce operational costs. As a strategic customer, Hummingbird, together with HP, will validate the improved system performance that will expand Hummingbird’s ability to enter new markets and applications.’

HP cited compostability certification for C500 as allowing converters and brands to improve the sustainability profile for corrugated packaging

To extend the sustainability credentials of PageWide, HP has had the digital corrugated packaging inks for its post-print direct-to-board C500 digital press tested and certified for compostability in home and industrial systems. 2 Din Certco of Germany, a leading global independent certifying body for compostable products, has certified the HP PageWide C500 CV150 HP inks with a ‘mark of conformity’ for the composting process, confirming the inks are, ‘additive harmless to the composting process.’

The successful testing verifies that HP PageWide C500 press prints can be used as packaging recoverable through composting and biodegradation in accordance with standards such as EU regulation EN 13432. HP PageWide corrugated inks were also tested and found recyclable by Papiertechnische Stiftung (PTS) of Germany using standard processes.

HP cited compostability certification for C500 as allowing converters and brands to improve the sustainability profile for corrugated packaging and contribute to a circular economy, in addition to printing on-demand quantities, reducing inventory waste, and lowering overall environmental impact.

A new set of Cloud-based PrintOS applications for HP PageWide C500 owners improve their overall site efficiency, and to optimise the management of their production floor, including:

- PrintOS Mobile App, a tablet or smartphone app that tracks real-time status and updates of job status and production improvements, such as daily count of printed square feet and press availability;

- PrintOS Print Beat, an optimisation app that delivers press and consumables historical and near real-time data for better, faster decision-making and improved print operations;

- PrintOS Jobs, providing jobs data including consumables, substrates, print time and more, and which enables streamlining of production status and job costing data such as substrate usage and time invested, to a management system (MIS or ERP), to understand the true cost of completed jobs for more accurate quoting; and

- PrintOS Supplies and Inventory Management App, which allows customers to optimise inventory levels.

Collaborations with the Fosber and Erhardt +Leimer (E+L) then enable synchronisation of digital pre-print to corrugator job changes within a roll, with options that can be part of new corrugators or retrofitted onto existing corrugators. Such relationships are intended to help the corrugated market digitally produce a mix of both long and short run jobs in a single roll with consistent, offset quality. End-to-end options simplify and accelerate the digital business growth of customers, according to HP, and as a result, converters can better respond to market demands dynamically with fast turnaround time, any minimum order quantity (MOQ), and a reduction in waste and inventory to increase market competitiveness without impacting the corrugator’s performance.

Carles Farre, vice president and general manager, HP PageWide Industrial, said, ‘Supply chains are facing pressures never experienced before, with market trends accelerated by the pandemic requiring converters to deliver faster and flexible packaging solutions. Digital packaging can fundamentally transform the corrugated supply chain for brands in high-volume and mainstream production, especially for e-commerce, food and household products. Time-to-market can be reduced from weeks using analogue methods to only days with HP digital, in addition to sustainability advantages of reduced waste, and higher shelf impact with greater design versioning.’