Jones Healthcare Group has installed a KOR Engineering VR4-330 rewinder to expand its capacity to produce high quality pressure-sensitive labels.

The Canada-based company is a provider of advanced packaging and medication dispensing options, and offers: graphic and structural design; print, conversion and filling of multiple packaging components including folding cartons, labels, blisters, pouches and convenience vials; and specialised medication adherence and dispensing products, and connected packaging.

Jones’ pressure-sensitive label capabilities include narrow and mid web print widths, UV and water-based flexo printing, and barcoding and sequential numbering. The new KOR VR4-330 includes a Domino inkjet module for back liner sequential numbering.

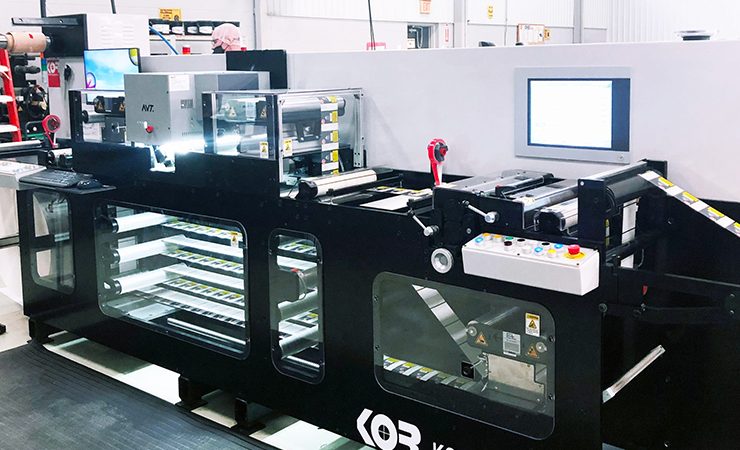

VR4 is a bi-directional rewinder available in a variety of widths. The reversing accumulator allows for 100% inspection and fault placement upstream of the vision system. The corrected web is then re-inspected by the vision system and allowed to pass through to the inkjet numbering, slitting and redundant counting stages.

Operational at the Jones Healthcare facility in London, Ontario in Canada, the rewind machine installed by the company features one-step quality inspection with an Esko/AVT web inspection camera, reversing error placement, and label reverification to ensure pharmaceutical quality expectations during the rewind process.

As well as generally supporting high volume pressure-sensitive label production, the KOR machine is also said to support and help Jones’ health and wellness customers get to market more quickly.

In a statement, Jones Healthcare Group said, ‘The VR4-330 complements our existing label equipment to expand capacity for our growing order volumes, processing a variety of pressure sensitive label constructions with quality assurance top of mind.’