UK converter Springfield Solutions has launched Digican, a can decoration option that utilises digital print technology to allow brands to showcase their products while reducing costs and storage requirements.

Specifically, Digican uses a full-coverage digitally printed label that is applied seamlessly to a can, giving the appearance of a printed can without the fallbacks of conventional print such as high minimum order quantities, high storage requirements and waste. The digital label is first applied to the flat tinplate blank, and then seamed into the top and bottom of the can. The label bleeds into the seams giving the appearance of a fully printed can.

A key benefit is that there are no MOQs and can packaging can be ordered as and when needed, so allowing brands to respond to market demand, as opposed to buying large quantities to meet high MOQs.

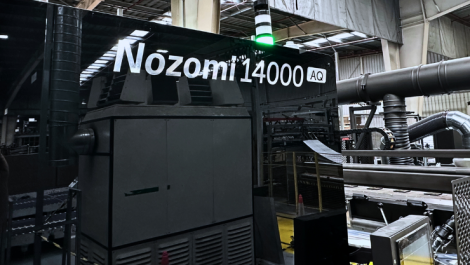

Digican uses Springfield’s fleet of Screen UV inkjet presses to create a can decoration solution that allows brands to showcase their products seamlessly while reducing costs and storage requirements.

The use of digital print technology to create the labels also means Digican packaging is fully customisable, with the potential to include customer names using variable data printing. Customisation and personalisation of packaging allows brands to differentiate their product from the competition and create an exciting experience for consumers.

The company asked, ‘Are you stuck using traditional methods with long lead times, high MOQs and little flexibility? Or simply want to upgrade your packaging to the next level?

‘Digican is designed for brands who are looking to utilise efficient packaging solutions and change the way that they package their product,’ Springfield Solutions stated.

Read the September/October 2021 issue of Digital Labels & Packaging for more from Springfield Solutions; register here to receive the magazine