A B Graphic (ABG) has hailed the inclusion of non-stop winding equipment in its finishing portfolio as ‘a resounding success’, responding to increased demand for efficiency and better output.

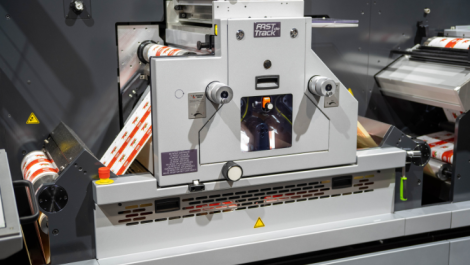

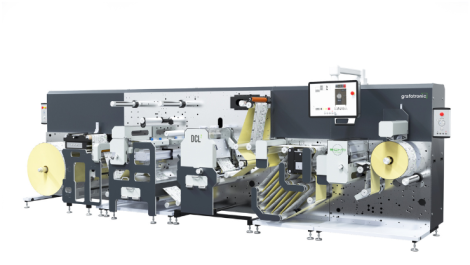

Introduced in late 2020, ABG’s non-stop unwinder (NSU) is designed to ensure the non-stop feed of web-type materials, while the non-stop rewinder (NSR) system provides continuous rewinding of a self-adhesive matrix produced with a label cutting and printing process. NSU/NSR units can work with any printing or converting equipment, and are noted as being of particular interest to customers with medium to long runs.

Since their launch, NSU/NSR equipment has been installed across Europe and North America.

ABG global sales director Matt Burton, ‘Prior to the inclusion of the NSU/NSR range into our finishing solutions portfolio, we saw that the market was increasingly demanding more efficiency and better output, so we set about meeting that requirement. Since launch, it’s great to see that customers are particularly happy with the service, installation and support that they are getting from ABG. Consequently we’re seeing repeat orders. Our non-stop one-stop-shop is very appealing to customers as they can come to ABG for their whole solution and our winder systems complement the complete range of ABG products, which helps increase overall flexibility.’