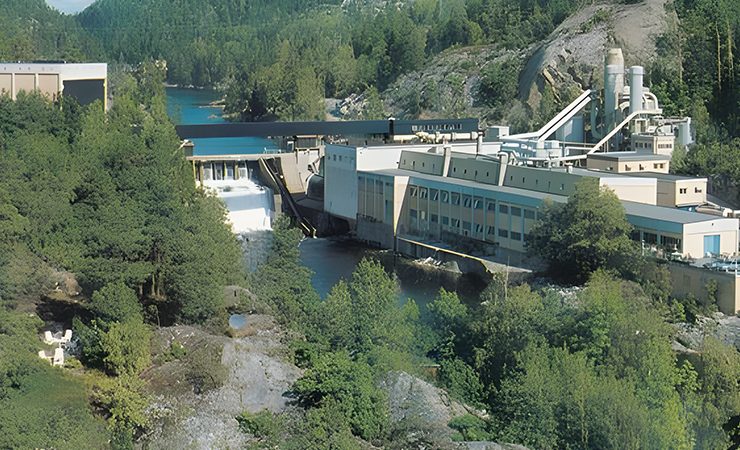

Vafos Pulp, a Norwegian producer of unbleached pulp for cardboard manufacturing, is to switch the energy-intensive drying process at its Kragerø pulp plant from oil to electricity, greatly reducing the plant’s carbon emissions.

The Kragerø pulp plant produces 80,000 tons of pulp each year. By replacing a nine megawatt oil-fired boiler with electric heaters, controlled by ABB technology, it aims to eliminate 14,000 tons of carbon dioxide annually from its production, starting from this summer. This is stated as the equivalent to the annual emissions of approximately 7000 combustion engine cars.

On a technical level, the air heaters require a significant amount of power and managing them is key to maintaining plant safety, operating efficiently and minimised downtime. For this, 10 ABB DCT880 power controllers are to be used to manage the power supplied to the electrical heating elements. The DCT880 power controllers feature the latest control technology and interfaces. This will enable the Kragerø plant operators to control the drying process more precisely than when they used oil. The switch to electricity also means that the facility no longer needs oil storage on site.

Roar Paulsrud, Vafos Pulp CEO, stated ‘The age of burning heavy oil in Norway is over. Customers expect us to be part of the green transition with sustainable production. It is also important that our industry helps reduce emissions here in Norway.’

Lars-Fredrik Mathiesen, head of ABB Motion in Norway, said, ‘The project in Kragerø is a great example of how organisations can decarbonise by using modern electric alternatives. As Norway’s grid is being almost entirely powered by renewable energy, moves like this one by Vafos Pulp lead the way for others in industry, and will be key to achieving the government’s goal of cutting carbon dioxide emissions in half by 2030.’