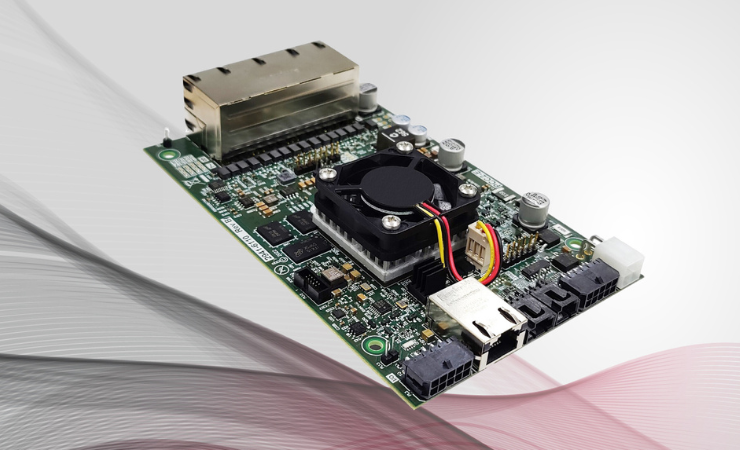

Industrial inkjet printing expert Meteor Inkjet has redesigned its print controller card (PCC), reducing its reliance on key computer chips that are in short supply around the world.

PCC is used by hundreds of OEM customers around the world to synchronise image data sent by a PC to arrays of printheads, such as those of Epson, Fujifilm Dimatix, Konica Minolta, Kyocera, Seiko, Toshiba TEC, Xaar and Xerox.

The original PCC was reliant upon an electronic component that is in critically short supply, ‘potentially delaying more than £4 million of printhead drive electronics,’ stated the company. Anticipating these long-term supply issues, Meteor Inkjet embarked upon a fast-track project to ‘re-architect’ the original PCC. In quick response to the diminishing availability of alternative components, the company identified a suitable replacement chip that was freely available in high volume, creating PCC2. Built with backward compatibility, the advanced chipset used in the PCC2 brings with it increased speed as well as the potential for future functionality enhancements. PCC2 is now shipping in production quantities, backed by the fact that Meteor Inkjet took the decision to acquire more than a year’s supply of the new chip before even starting development.

Jonathan Wilson, Meteor’s vice president of business development, explained, ‘Our products are trusted as the most reliable components with which to build an industrial inkjet printer. Our customer base, having grown over the last decade to make Meteor the largest datapatha supplier in the industry, had to wait for us to find a solution to what continues to be the worst chip supply shortage ever. I am delighted that their patience is now being rewarded, and we will quickly clear the order backlog that developed over the last two quarters.’

During the development of PCC2, Meteor Inkjet worked closely with a handful of companies including Dantex Digital. Richard Hall, the inkjet digital press manufacturer’s R&D director, said, ‘We have been pleased to participate as a beta site for Meteor’s PCC2 development. Supply chain issues, and particularly shortages of electronic components, have taken their toll and we are happy to work with collaborative partners that demonstrate resilience and customer focus.’

Meteor Inkjet managing director Clive Ayling said, ‘It is a source of immense pride for everyone at Meteor that this enormous task has been achieved. In particular, praise is due to our engineering team in Cambridge who pivoted their attention to this one project which has resulted in a robust, backward-compatible replacement product for our customers in record time.’