Digital print finishing specialist Duplo has developed and launched DDC-8000, an industrial scale B2 digital spot UV coater that firmly puts its DuSense technology in sight of the packaging industry.

DDC-8000 is able to handle a sheet size of 585 x 1068mm, with a maximum printing area of 538 x 1048mm. According to Duplo, such a size helps futureproof an investment as digital press sheet sizes are getting wider. Some, such as the Fujifilm Jet Press, already offer a 585mm width. Foiling is done inline with a cold process, and corona treatment removes the need for lamination prior to printing. This step also allows a single varnish to be used to treat the surface and make it applicable for print from all types of press, be they Indigo, inkjet or offset, etc.

The system is fully modular, with four options available. Printers can adapt the machine according to their needs. Regardless of the spec chosen, DDC-8000 delivers 600 x 600dpi print using five Kyocera printheads. Variable heights can be achieved with the varnish and foiling. A UVA LED lamp is then used to pin the coating before the foil is applied, and final curing via a UV mercury lamp. This final step has been included in order to allow full and proper curing with a 40 micron coating depth, and print speed of 1500 B2 sheets an hour. A coating range of 10-80 microns can be achieved.

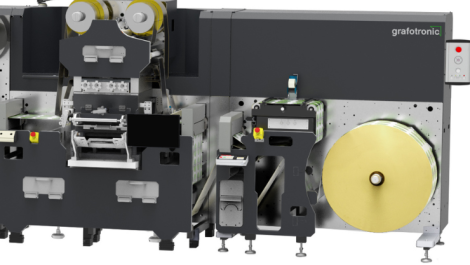

Being modular, machines can be specified as ‘Essential’, with feed and print capability; ‘Foil’ with the addition of a foiling module; ‘Pro’, which combines feeding, treatment and printing; and the DDC[1]8000 Ultimate with feed + treat + print + foil. Such a system is installed at Duplo UK’s headquarters and was demonstrated at a recent open house event.

DDC-8000 builds on the success of the earlier DDC-810 but with upgrades and additions that make it applicable for a broad range of applications. Most noteworthy is an automatic thickness detection (ATD) system that measures the thickness of every sheet and adjusts the printheads and foiling for optimum results. With DDC[1]8000 able to handle substrates from 160-600gsm, this allows the machine to handle mixed stock media in a single operation.

Samples produced using DDC-8000 will be on show at The Print Show 2022

Samples produced using DDC-8000 will be on show at The Print Show later this year in September at the NEC in Birmingham, UK.

Duplo managing director Martyn Train said, ‘Since a hugely successful event of our own in May at Duplo HQ [where DDC-8000 was introduced], we’ve seen how busy other industry events have been through the last few months. We are going to The Print Show to showcase our new solutions to what I’m sure will be a busy show floor and can’t wait for September to roll around.’