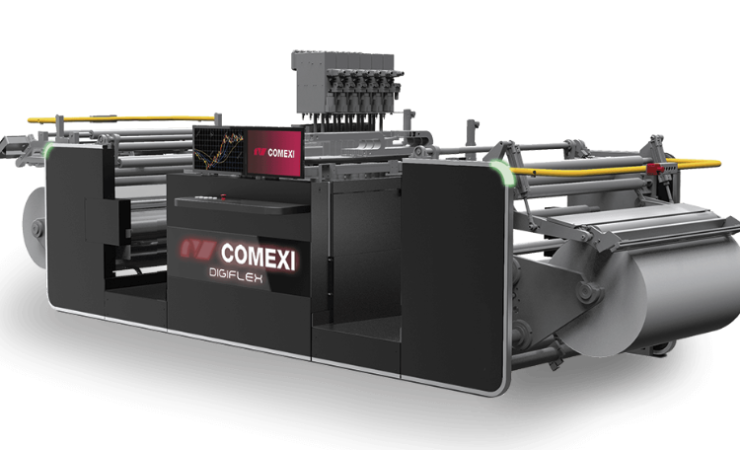

Comexi is getting ready to unveil the new Digiflex, which offers digital printing of variable data, such as Datamatrix variable codes, QR codes, barcodes, alphanumeric text, as well as other numbering and marking applications with high quality requirements.

Digiflex uses low-migration inks that are suitable for food packaging printing and allows for the possibility of double-sided printing without treatment, as well as printing on pre-printed material. The Digiflex has a reduced set-up time and can reach a maximum speed of 220m/min, reduce material waste, and improve lead time. The machine offers high printing quality with a resolution of up to 1200 x 1200 dpi, a minimum code size of 8 x 8mm, as well as printing and registration consistency.

Pedro Jiménez, digital technical sales director at Comexi, said, ‘Comexi Digiflex is the machine that currently offers preeminent digital printing of variable data, such as Datamatrix variable codes, QR codes, barcodes, alphanumeric text, as well as other numbering and marking applications with high quality requirements. It is a digital variable data print press that offers extremely high printing speed, superb quality results, as well as the highest level of performance and production. Digiflex is an all-in-one solution that includes the integration of the curing process, tension control, printing registration, corona treatment, and a video inspection system.’

Using Digiflex to print variable data means each printed code can be different and contain unique information, providing traceable material information, thus personalising products according to the consumer’s needs, and protecting brands from counterfeiting. Mr Jiménez explained, ‘The Digiflex codes tracks and traces each product, complying with legal requirements as well as contributing to the circular economy, serialization and security of the supply chain. [This] helps boost customer awareness, brand loyalty and feedback acquisition, and also enables the analysis of consumer behaviour. Finally, the Digiflex offers security, anti-counterfeiting, and authenticity solutions, which is highly valued by brand owners.’

As further example of the capability of Digiflex, Comexi participated in the R-Cycle project, led by the Reifenhäuser Group. Unique codes printed using Digiflex identify the plastic type and performed production processes of each packaging unit, which makes recycling more appropriate and efficient.

Sustainability has become a primary global concern in recent years and consumers are increasingly aware of the environment and do not hesitate to buy sustainable products. Comexi claims to offer flexible packaging with a lower carbon footprint, efficient energy management, less material loss, lower ink consumption, as well as reduction of plastic usage and solvents.

Enric Carrera, chief commercial officer of Comexi, said, ‘Our goal is to provide products and services that help converters offer added value solutions to their customers. For this reason, in regard to equipment that adapts to the current market needs and requirements, we innovate with consistency.’

Digiflex will be revealed at K – a trade fair for the plastics and rubber industry from 19 to 26 October at the Messe in Düsseldorf.

Lamination business unit director Albert Chicote added, ‘We are supplying unique solutions for water-based coatings applications onto paper and film, that are significantly reducing the environmental impact.’

Comexi claims it has a strong focus on automation during the laminating process and will show its closed-loop system which provides reliability of the coating weight during a job run without any human intervention.

Mr Carrera said, ‘Comexi Laser is the revolution of the flexible packaging industry. A laser-in-line processing system can be integrated into Comexi slitting machines. It is the key differentiating technology that optimises production and follows the most recent technology developments and market trends.’

The company offers the possibility of automating every operation that occurs after rewinding and slitting, such as transport, labelling, weighing, bagging, and palletising.