Global Inkjet Systems Ltd (GIS) has expanded its support of Epson Precision Core printheads to offer flexible drive electronics and software for the full Epson S800 series (U1, U3, A1 and S1) via the GIS Ethernet platform.

GIS has developed this additional printhead capability to provide system integrators and OEMs with even greater industrial print system development opportunities, including direct-to-shape and materials deposition markets.

The Epson S800 printhead series uses PrecisionCore technology, enabling high speed, high quality printheads with consistently accurate drop placement for optimum image quality. Its compact design, along with a printhead depth of 8.3mm and distance between the two nozzle rows of just over 1.0mm, makes the Epson S800 well-suited for direct-to-shape printing onto curved or complex surfaces.

Its single colour, 600dpi output is compatible with a broad ink capability (the U1 and U3 variants for UV inks, A1 for aqueous and S1 for strong solvents used in some coatings and functional fluids).

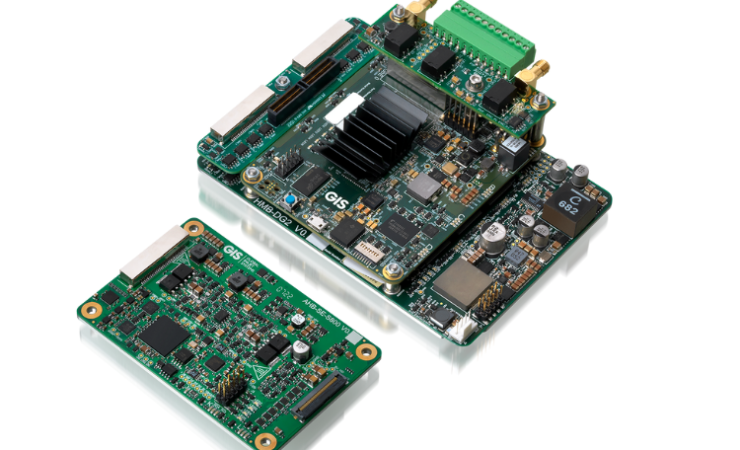

Support for the Epson S800 printhead series is achieved through the GIS HMB-DG2 Ethernet Head Management Board (HMB), and a new GIS Analogue Head Board (AHB), the AHB-SE-S800, to drive each S800 printhead variant to its full potential.

The GIS HMB-DG2 / AHB-SE-S800 configuration has a flexible design and can drive up to 2 x Epson S800 printheads. It comes with an option to add up to 2 x stackable daughter boards to support up to 6 x printhead connections and multiple HMBs can be scaled to support larger systems. The HMB-DG2 includes print data management, waveform control and printhead diagnostics, all accessed over Ethernet. The GIS datapath hardware is complemented by Atlas® software offering optional RIP, VDP and Image Quality (IQ) Tools to achieve the high-quality, demanding printing requirements of industrial applications.

Debbie Thorp, business development director, said, ‘We are delighted to expand our support for Epson printheads and see great opportunities for the S800 printhead series for customers looking for the next step in higher resolution direct-to-shape printing and for the ever-expanding market for functional fluids.’