Bobst has developed a 3D visualisation tool to allow customers to create and visualize the exact Digital Master series press configuration they need for their business.

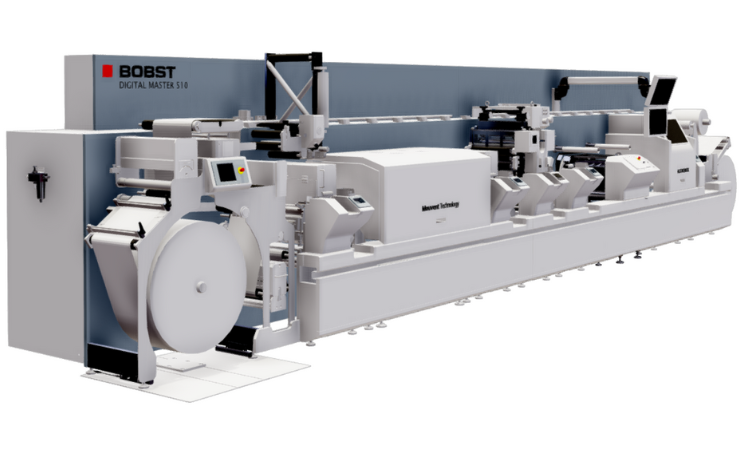

Having launched the Digital Master series earlier this year. These hybrid – all-in-one, all inline – systems combine digital and analogue technologies in a single press. Available with 340mm and 510mm print widths, they are based on a fully modular and upgradable architecture, this enables customers to build a press that fulfils their current and future needs. As stated by Bobst, ‘by integrating digital and flexo technologies into one workflow, label converters can enhance their capabilities, reduce waste and improve efficiency.’

This is now taken a step further with 3D Configurator, an online tool that allows customers to create and visualise the exact press configuration they need for their business. This tool gives converters instant online access to view all possible modules, including flexo, delam/relam, multi-layer, combo coupon, hot foil, combo lamination, screen printing, and semi-rotary/rotary die-cutting. These modules can be added, arranged, combined or removed from the base machine, and each module is visualised in 3D with descriptions detailing their use and potential.

Once the configuration has been finalised, a full report with the details including press dimensions, will be presented. Customers can also get in touch with their local Bobst sales representative via the online tool to discuss and validate their choices.

Bobst’s Digital Master series 3D Configurator is compatible with both desktop and mobile devices and can be accessed here.

Patrick Graber, strategic marketing manager at Bobst, commented, ‘We understand that every customer has unique requirements, which is why we have developed the unique Digital Master series platform. Now, converters can experience the modularity and versatility of Digital Master series with the new 3D Configurator, which enables them to configure their press based on their specific requirements.’