Screen Europe is to introduce enhanced automated colour calibration technology for its Truepress Jet L350UV series of digital label printers, intended to make colour management faster, easier and more accurate.

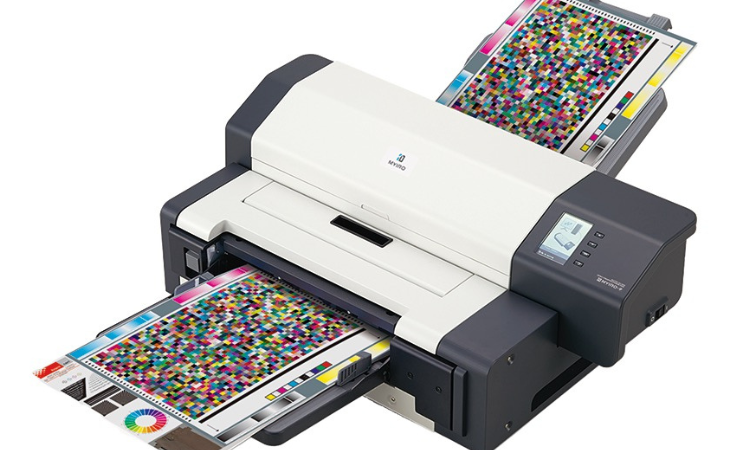

Introduced initially for the company’s Truepress Jet 520HD, Myiro has been developed by Konica Minolta Sensing as a sophisticated colour management workflow, combining software and an autoscan spectrophotometer. All steps in the calibration process are integrated into one and the same software. The tool guides the user intuitively through the workflow setting for density adjustment, linearisation and ICC profiling. Using the autoscan spectrophotometer, measuring processes are easier to handle and can be done around four times as quickly. Each calibration step takes just a few minutes in addition to the printing time, with the entire calibration process now being completed in 30-45 minutes. This means that, compared to the old calibration process, around 90-120 minutes are saved per machine set-up and added to production time.

In the case of Truepress Jet 520HD printers, colour calibration was mostly done manually by technicians. It was a complex process, as noted by Screen Europe, with many steps and chances for error and could only be handled by experienced colour experts. It could easily take several hours before a printer was completely ready to run. In the course of 2023, it will be possible to use the Myiro system for the company’s Truepress Jet L350UV series.

Taishi Motoshige, marketing director at Screen Europe, said, ‘The big difference with our previous system will be the standard built-in quality control, complying to common industry standards such as Fogra PSD, G7 Verify and ISO validation print, because this is what our customers will use every day. Thanks to the spectrophotometer, our customers will detect colour differences before the human eye can see them, earlier than before and in much more detail. The Myiro software detects itself where the spectrophotometer has to measure. This level of quality management and automatic recognition makes Myiro one of the most accurate measurement technologies in the market.’

Markus Hitzler, technical sales manager, graphic arts at Konica Minolta Sensing Europe, said, ‘Colour calibration is the essential, final step in the setup of a printing process. This step ultimately determines whether the qualities of the press, paper and ink can be fully utilised. It also has a significant influence on commercial aspects, such as ink consumption. Only with perfect calibration does the machine print exactly what the designer created.’