Bobst has formalised a multi-year strategic partnership with additive manufacturing and 3D printing specialist Sauber Technologies for the supply of 3D printed parts, engineering and development expertise for inkjet label presses.

Whilst Bobst is a global manufacturer of converting equipment, Sauber Technologies is part of the Sauber Group of Companies and offers 3D printing of metal and plastics parts, produced with the same advanced processes and techniques that are used in Formula 1 race cars. Specifically, Bobst’s new engineering partner will manufacture parts for the 3D printed Cluster, which is used in Mouvent inkjet digital printing technologies brought to market by Bobst.

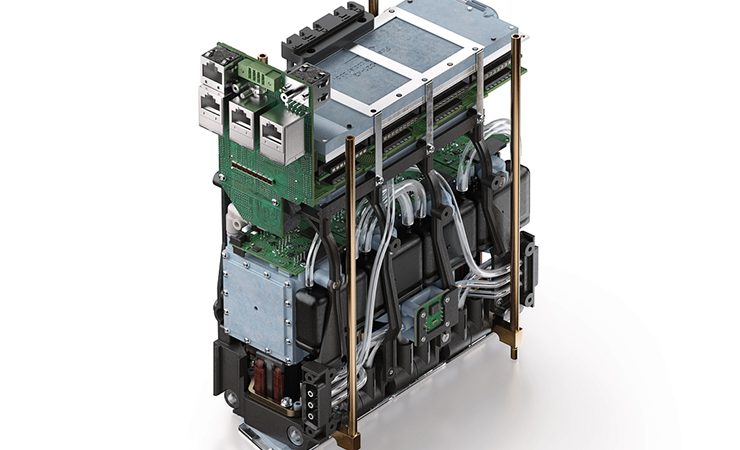

This will support the scaling up of production to meet demand for Bobst’s range of ‘all inline, all-in-one’ label presses. With the agreement coming into effect on 1 January, 2023, Sauber Technologies will shortly begin serial production of parts for the Cluster technology, which integrates all ink management, electronics and mechanics with the printheads in one scalable matrix. As this ‘highly flexible and stable technology’ can be adapted for any substrate and application, Bobst described it as, ‘the obvious choice for powering the digital printing presses of the future.’

Léonard Badet, head of group technology at Bobst, said, ‘With its expertise and leading 3D manufacturing technology, Sauber is known for always pushing the boundaries of innovation and this makes the company the perfect engineering partner for Bobst. As technology leaders in our respective fields, there is a great synergy between our two companies, and we are excited to implement F1 technology into our inkjet engines in what will undoubtedly secure our place at the top of the podium and keep us there going forward.’

The technology partnership will also enable Bobst to accelerate its innovation strategy for the future of packaging production.

Jonathan Herzog, chief commercial officer at Sauber Technologies, said, ‘We see this agreement as the beginning of a fruitful partnership and look forward to supporting Bobst in elevating its printing equipment to the next level.

‘With the largest and most modern additive manufacturing facility in Switzerland, Sauber Technologies is dedicated to the development of high-end additive manufacturing for the widest spectrum of industries, whether that is F1 racing, energy supply or industrial label manufacturing.’