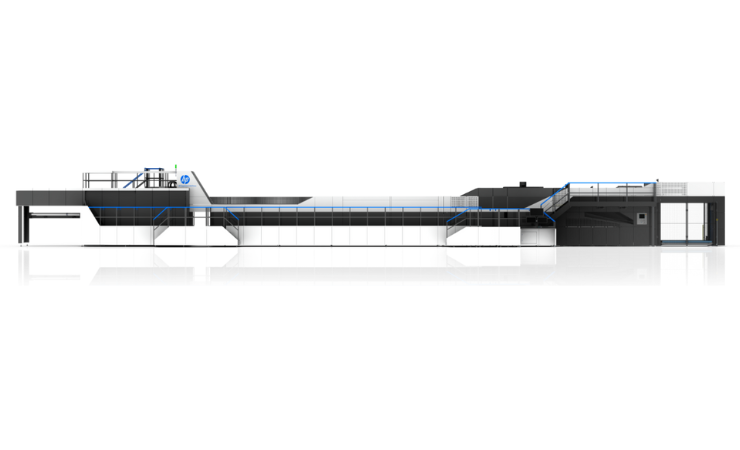

HP has developed C550, the newest model within its PageWide portfolio of presses for high-speed, post-print digital corrugated manufacturing.

Based on the existing PageWide C500 press, the updated model is claimed to offer ‘enhanced productivity and value’ to the industrial packaging industry. The HP PageWide C550 uses HP’s thermal inkjet (TIJ) technology and ‘true water-based inks’, to deliver consistent offset print quality at fast production speeds – 90 linear m/min – while also supporting packaging converters’ circular economy goals through optimising inventories, reducing obsolescence and accelerating turnaround times.

Moreover, HP stated that, by enabling improved economics, greater production versatility and more sustainable packaging solutions, PageWide C550 presents a ‘significant opportunity’ for business growth for converters facing increasing supply chain pressure.

David Tomer, general manager of HP’s post-print corrugated solutions, said, ‘HP is continuing its investment in the packaging market to create new opportunities for packaging converters and brands to benefit from the analogue to digital transformation.’

One such company is Spanish corrugated packaging specialist Saica Group, which has ordered a PageWide C550 press for its operations in Viana, Spain. The company is said to be committed to digital transformation and, ‘using innovative technologies to respond to the growing demand for shorter and customised runs.’ The new press is set to be installed later this year and will support increased plant capacity for corrugated packaging production.

In this regard, HP has also collaborated with Hybrid Software on pre-press workflow for packaging, making it easier to transition artwork from litho and flexo formats to digital. This relies on Hybrid Software’s Packz PDF editor product to provide automated actions and dedicated pre-press tools. Packz can help make designs ready for any print process, by enriching them with priming and finishing separation, handling ink sets and object-based screening, as well as applying trapping and generating dynamic marks and panels. Specifically for those using the PageWide C550, HP noted that Packz will enable converters to prepare files efficiently and reduce errors, making the pre-press process ‘easier and more productive’.

Mr Tomer continued, ‘We are very excited to deliver the C550 press to the corrugated industry. It is built on the field-proven success of the C500 press and allows converters to economically produce flexo and litho boxes at high speeds without slowing down the press. We are constantly working on innovative solutions that not only improve post-print stability and productivity for converters, but also meet the quality and flexibility demands of brands for packaging.’