Fujifilm is to use this year’s returning interpack exhibition to showcase its growing digital package printing portfolio.

Taking place in Dusseldorf, Germany across 4-10 May, 2023, interpack is a global exhibition for packaging industry value chain. The show’s focus is on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. Printing and notably digital technologies have a presence at the show.

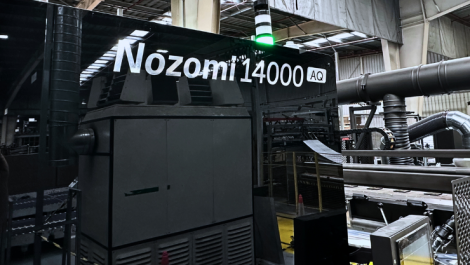

This year, Fujifilm will be amongst those showcasing their digital printing capabilities with respect to the next generation of packaging. This will see the Jet Press 750S high-speed model running live and producing folding carton packaging in conjunction with a Kama finishing unit. The Jet Press FP790, a digital flexible packaging press, will also feature. This press is designed to offer a digital alternative to flexo production for mainstream applications and print runs of flexible packaging and, ‘meets the strategic needs of businesses faced with the challenge of dealing with the proliferation of SKUs, a widening variety of products and shorter delivery times,’ according to Fujifilm. The company’s imprinting systems provide printers and converters with further options to add digital, which can be integrated directly into existing analogue production lines.

Such systems will be presented alongside analogue technologies – water-washable flexo plates, narrow web flexo inks and UV LED curing systems – leading Manuel Schrutt, head of packaging in EMEA at Fujifilm, to state, ‘We work with packaging producers at all stages of their journey, whether it’s helping them to optimise analogue production lines to maximise efficiency or to introduce a digital capability. We don’t do one-size-fits-all – we do the right solution, for the right producer, at the right time.

‘All of our solutions, whether analogue, digital or somewhere in between, are designed to reduce waste and the use of environmentally harmful chemicals, minimise energy consumption and to be as sustainable as possible.’