Xaar, the inkjet printing technology group, has invested approximately £1.2 million in its printhead manufacturing facilities, as the company continues to focus on improving its operational and energy efficiency.

The end of the ten-week project provides Xaar with smart factory manufacturing for its inkjet printheads, but also delivers sustainability benefits, and a rapid payback on the investment.

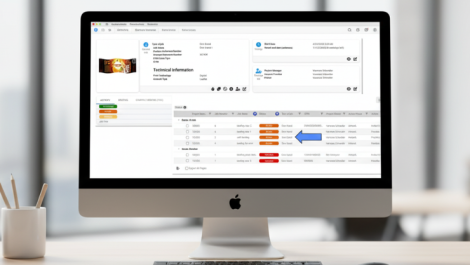

Through setting up a digital twin of its cleanroom, workflows have improved, and waste and inefficiencies have been reduced. This digital version of the factory, has meant that Xaar have been able to assess and analyse the production process at all stages and is as efficient as possible. By installing smart meters, the company is also able to track energy usage every five minutes, enabling the business to identify and eliminate any areas of energy wastage with analysis of this data.

Maintaining the temperature and air handling in cleanroom areas is extremely energy intensive and by reorganising the space from four clean room-controlled areas to three, and separating off part of its footprint, the company expects to reduce energy usage by up to 40%.

Paul Shepherd, head of engineering at Xaar said: ‘This project has major outcomes from a sustainability and manufacturing perspective, through enabling us to intelligently manage our production. Our flexible cleanroom and upgraded equipment and services, will save significantly on our energy consumption at Huntingdon, while continuing to ensure we provide the industrial inkjet printheads our growing global customer base demands.’