First Tape & Label (FT&L), a provider of tyre and industrial labels located in Texarkana, Arizona, has employed a 3800 Series UV inkjet engine from Colordyne Technologies to produce single-pass inkjet labels for its customers.

With over 40 years of experience, FT&L provides tough and durable labels in the industrial label market. The converter also produces a signature pressure-sensitive label stock in-house, adapting to the needs and demands of each of its customers. The integration of the UV inkjet engine allows the converter to increase productivity and profitability with single-pass process colour inkjet.

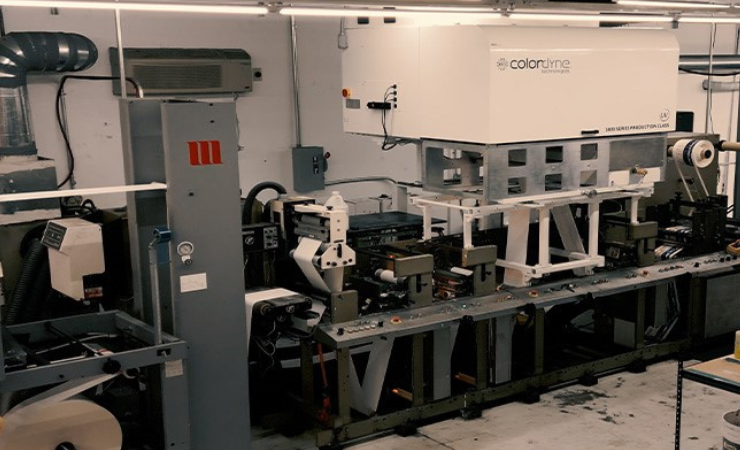

The label converter acquired its first Colordyne engine, a 3600 Series UV – retrofit, in 2020. After experiencing faster turnarounds and cost savings through the integration of inkjet technology, FT&L acquired an additional second-generation 3800 Series UV – retrofit in 2021. The new inkjet engine is mounted on an existing flexo press and it showcases an automatic splice system and job-changing software that allows them to gain efficiency and speed in its daily throughput.

‘With the Colordyne UV inkjet engine and our job-changing software we can produce all types of jobs at high efficiency: short runs, long runs and high mix projects,’ commented Jennifer Chesshir at First Tape & Label. ‘We are able to layout and schedule hours of production quickly, eliminating the creation of single-use artwork. Our single pass digital setup allows us to provide the highest quality at the best price point for each specific job.’

‘We are excited to see the success FT&L experiences with the UV inkjet engine from Colordyne,’ said Taylor Buckthorpe, director of sales and marketing at Colordyne Technologies. ‘Increasing productivity to deliver the best service and product to its customers is FT&L’s priority and we are happy to support them in achieving it.’