Fujifilm North America Corporation has named Kongsberg PCS as the preferred supplier of its Graphic Communication Division for digital cutting tables to the sign and display, packaging production and manufacturing markets.

Through this partnership, Fujifilm will distribute and sell all Kongsberg PCS digital cutting systems across the US and Canada.

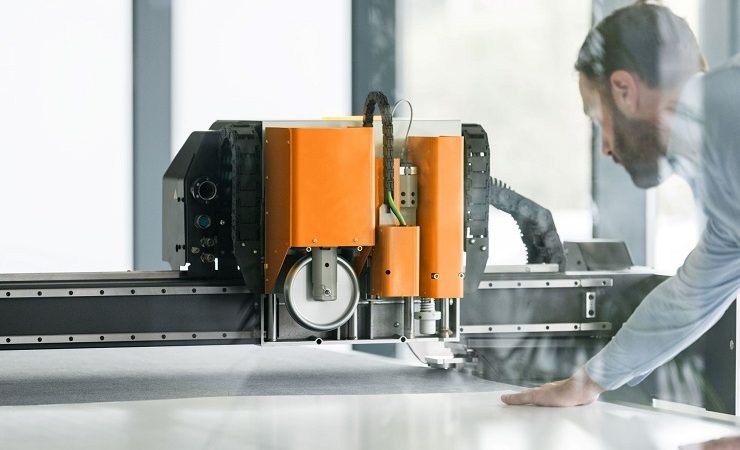

By partnering with Kongsberg PCS, Fujifilm customers will have direct access during the purchase process to cutting system systems for multiple materials, including folding cartons and packaging, labels and decals, POP displays, banners, wall graphics, aluminium signs and flexo plates. By integrating Kongsberg’s precision cutting technology with Fujifilm’s graphic printing technologies, ‘print service providers can maximise efficiency by streamlining their production processes, resulting in fast turnaround times, high output and low costs,’ stated Fujifilm.

Toyoyuki (Tommy) Katagiri, president of Fujifilm North America’s Graphic Communication Division, said, ‘Kongsberg PCS is highly regarded as one of the most reliable, innovative finishing/cutter device manufacturers in the wide format market. This partnership demonstrates Fujifilm’s commitment to a ‘whole solution’ approach; we are with our customers from start to finish, offering complete printing and finishing solutions in one easy-to-implement package.’

As part of this partnership, Kongsberg PCS will not only provide Fujifilm and its customers with sales, service and support for the Kongsberg precision cutting platforms, but will also offer ongoing training and technical support to Fujifilm customers throughout the lifecycle of their cutting system.

Matt Thackray, vice president and general manager of the Americas at Kongsberg PCS, said, ‘Kongsberg digital finishing solutions are designed to meet the increasing demands of the packaging, sign and display, graphics, and corrugated industries. With their advanced features and capabilities, Kongsberg’s digital finishing/cutting platforms will help provide Fujifilm customers with elevated accuracy and versatility while maximizing productivity.’