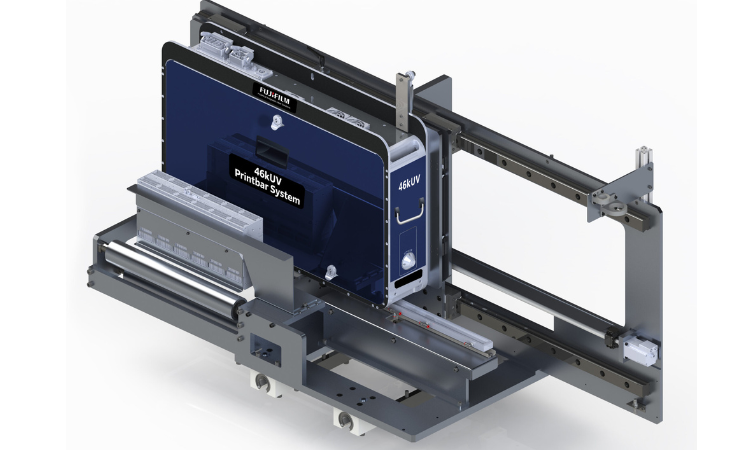

Fujifilm has launched 46kUV inkjet printbar system worldwide for industrial production operations across a wide range of labels and packaging materials.

The 46kUV inkjet printbar system features a drop-on-demand design to streamline workflow with printing speeds of up to 150m/min. It also uses Fujifilm’s proprietary Samba printhead technology, which leverages the precision of silicon MEMS processing and sputtered PZT.

The system has a resolution of 1200dpi to cover a label quality needs. The 46kUV inkjet printbar can also print individually unique QR codes, as well as fonts as small as 2 point.

Vice president and general manager of the Fujifilm integrated inkjet solutions group Greg Balch commented, ‘We’ve seen the use of inkjet continue to grow in the label and packaging markets given its ability to produce high-quality output with variable data.

‘Our vision behind the 46kUV inkjet printbar system is to help fill an important gap in the market for imprinting at high dpi and with high reliability.’

Other benefits of the 46kUV inkjet printbar system, explained by Fujifilm, is its availability in various print widths of 254mm, 330mm, 432mm and 508mm to integrate seamlessly into traditional printing processes.

The printbar’s cleaning and capping module is designed to help maintain image quality and the use of Fujifilm’s proprietary Redijet patented ink recirculation helps optimise image quality across the print width minimising the need for printhead refurbishment.

Manuel Schrutt, head of packaging, Fujifilm EMEA concludes stating the ‘innovation showcases how our technologies in analogue and digital can go hand in hand,’ which opens ‘new ways of production for customers.’