DataLase, a laser coding and marking solutions company, has launched a new range of colourless to white coatings for a range of packaging applications.

Centred on a biodegradable and sustainably sourced raw material, the coatings are claimed to provide a highly contrasting white print at flexographic and gravure coat weights, even on substrates such as 12-micron PET and shrink film. The range includes pad printable coatings, for direct-to-shape marking of objects, such as bottles, caps and closures.

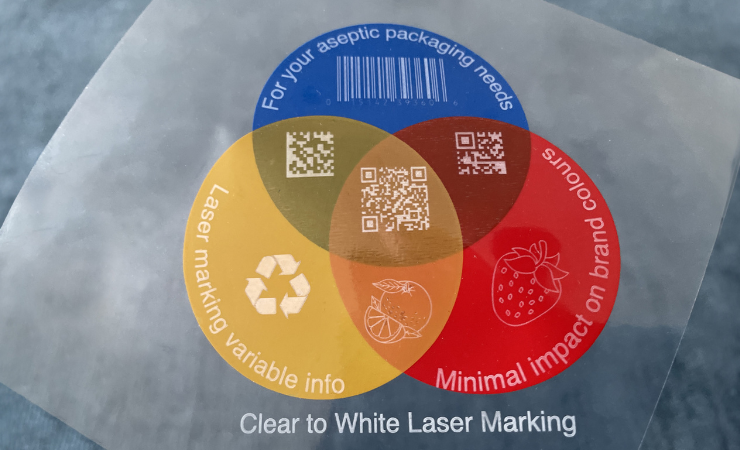

The ‘versatile’ coatings are also available for folding cartons, flexible films, foils, pouches and labels. High opacity, high-print quality and QR code readability are realised across a range of lasers, providing CO2, fibre and UV lasers, offering multiple options to accommodate different user needs.

In contrast to laser ablation, these coatings are said to eliminate ink debris, odour and off-gassing, making the coatings ideally suited for aseptic packaging, also enhancing the lifespan of filters and extraction equipment. Also explained by the company, the coatings permit higher speed laser imaging than laser ablation, thereby increasing production throughput and, at lower laser power, extended laser working lifetime.

The coatings provide white marks via a metal-free, naturally occurring alternative to titanium dioxide, which is commonly used in conventional and digital inks. This sustainable chemistry and resultant coatings are protected and held by DataLase.

DataLase’s CTO, Ally Grant, said, ‘In line with the high expectations set by our market-leading coatings and pigment technology, our innovative clear-to-white coatings are designed to reduce consumables and waste in production environments.

‘They not only enhance throughput and productivity, but also feature scuff and rub resistance, which minimises the need for potential rework and further waste.

‘These coatings are versatile enough for product coding applications across various industries, including food & beverage, home & personal care, pharmaceutical and medical.

‘They are compatible with a wide array of substrates such as filmic materials, paper and plastics, making them ideal for use on pouches, laminates, and bottles.’