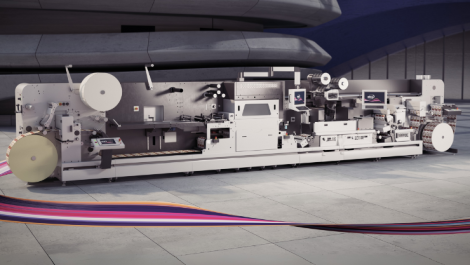

Xeikon has revealed details of its next evolution Panther inkjet technology, the Xeikon PX3300HD, a new 1200dpi digital press that will be launched at drupa 2024, Hall 11, booth A01.

Developed for high quality labels, the five-colour machine offers a 330mm printing width and speeds up to 70m/min, even when printing with high opacity white. To ensure ‘perfect’ curing, the Xeikon PX3300HD utilises a newly developed ink series, PX-Cure LED HD, which is also said to support sustainability targets for converters.

‘As inkjet technology continues to mature, there’s a clear need to update Xeikon’s Panther portfolio with a higher resolution option to meet specific customer requests. Consequently, we’re now introducing a 1200dpi engine to complement the existing 600dpi product range,’ stated Jeroen Van Bauwel, Xeikon’s director of solution design. ‘The new Xeikon PX3300HD will extend the capabilities for printers by giving them the tools to reach excellent quality at even higher productivity levels in a TCO-friendly way (total cost of ownership).’

Described as a small footprint machine, the Xeikon PX3300HD produces durable, full-colour labels for diverse markets, covering up to 88% of Pantone colours within Delta E 2 (rising to 94% within Delta E 3).

To meet the specific requirements of the higher resolution engine, Xeikon has developed new PX-Cure LED HD inks. The new inks match the sustainability benefits of the recently introduced PantherCure UV LED series for Xeikon 600dpi inkjet presses, including significant savings in energy consumption, instant warm up for more agile operation, and 10 times longer lamp life compared to traditional UV arc lamps, resulting in lower waste.

Combining high image quality and resolution with productivity, the new press leverages Xerox W-Series industrial inkjet printheads with dedicated waveforms and screening software developed by Xeikon. Furthermore, the PX3300HD is fully prepared for hybrid printing to increase productivity, with the option to add Xeikon’s modular inline LCUs (Label Converting Units) and a large unwinder for longer uninterrupted production runs.

Driven by the Xeikon X-800 DFE (Digital Front End), the press can supply a faster job turnaround and just-in-time delivery. Colour management, as described the company, is an integral part of the software. Every X-800 comes with a Pantone license so customers can convert all the latest Pantone colours for their press and substrates. In addition, the basic press configuration offers efficient operational support with an inline camera for quality inspection included by default. Adjusting registration, stitching and compensation for missing nozzles are all measured and corrected in a fully automated way. This feature also helps to alleviate ongoing issues with finding skilled staff to run the press, while extending the lifetime of the printheads and ensuring consistent high quality.

Van Bauwel concluded, ‘This extension of Xeikon’s inkjet capabilities is an incredibly exciting development for customers. It offers them a very cost-effective and highly competitive opportunity to scale their businesses, so they can supply profitable luxury market segments with exceptional productivity and quality. We are currently well underway with customer trials and will start sales at drupa.’