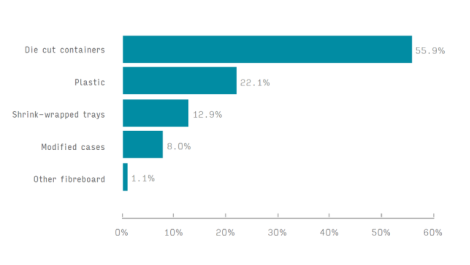

DS Smith, global manufacturer of fibre-based sustainable packaging solutions, has aided global snacking company pladis to reduce plastic in its orange Jacob’s Cream Crackers box, while still delivering a tamperproof pack with impactful branding.

After rigorous testing by DS Smith designers, the finished product featured 78% less plastic per pack, saving over 373,248kg of CO2 so far. All the while incorporating high quality print to the same standard as the previous solution.

Paul Bridge at DS Smith, said, ‘Now more than ever, consumers are concerned about the amount of plastic in their packaging. We were delighted to work with pladis on new packaging for their iconic Jacob’s Cream Crackers. The challenge with attempting to cut plastic out of packaging often means it can compromise the design. By applying our unique Circular Design Metrics, we came up with a solution that ensured that we ended up with a finished product that had 78% less plastic, while retaining the same high-quality print as the previous packaging.

‘The new design is already on-shelf, and we’ve taken the learnings from the project to see how we can apply them to future solutions we work on.’

David Guy, packaging director at pladis UK and Ireland, added, ‘Redesigning our packaging was a big moment for us, especially as Jacob’s is such an iconic brand which customers know and love. We were delighted to work with DS Smith, and they really hit our brief, finding a solution which worked with our current manufacturing set up without compromising on branding.’

In line with its ‘Now and Next’ strategy and purpose to redefine packaging for a changing world, DS Smith uses its unique Circular Design Metrics to rate and compare the circularity of packaging designs across eight different indicators.

Since its creation in 2019, the DS Smith Circular Design Metrics have supported thousands of design projects with around 3000 circular-ready projects presented to customers every month.