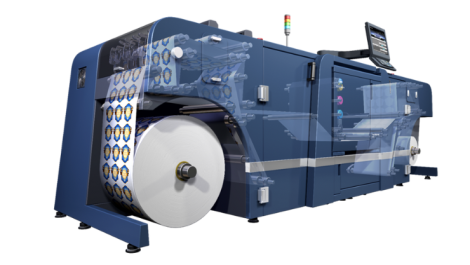

HP launched the PageWide T700i inkjet press at an event attracting 30 potential customers – as well as the first company to order one – at an event at Koenig & Bauer’s Würzburg facility where the machine is made, reported Sean Smyth. K&B supply the reel handling and paper transport base while HP make the printing units and frontend. The machine is smaller that the T1195i for corrugated liner at a print width of 1.7m with a maximum frame length of 2.7m, but runs at the same top speed of 305m per minute.

It is ten years since the relationship between K&B and HP started and the two companies have succeeded in changing the face of high-volume pre-print for corrugators, now they hope the T700i will do a similar job for litholam where the laminators can be much more efficient than using sheetfed laminators. The press will have continuous unwind into a flexo priming unit, then for uncoated papers there is an inkjet bonding agent station, six-colour inkjet (CMYKOV) into a new four stage drying section. Then a flexo coater, that could be Conprinta station for spot and effect varnishes, into a remoistener and then into a rewinder.

Initially the press is being aimed at corrugated, either as top liner for a corrugator or for a webfed laminator onto an open face stock and it could run paper flexibles for e-commerce wraps and bags. The maximum grammage is currently set at 250gsm but there are plans to increase this, which will make it very interesting also for cartons. It features 196 of the latest 1200dpi thermal printheads, the G5i models that offer excellent print quality and improved reliability and durability over previous models. The press architecture allows for very fast swap out of heads in the event of a problem.

HP announced the first company to buy a machine is Pratt Industries, at their facility near Atlanta where it will be used to replace litholam that they currently outsource. Delivery is scheduled for autumn with the machine scheduled to come on stream early in 2025.