From its production site in Stuttgart, Germany, Koenig & Bauer (K&B) MetalPrint will be helping its customers to achieve sustainability goals; equipping all factory-new printing systems with the hardware required to record energy data, configuring them with VisuEnergy X energy management system for complete data monitoring and reporting.

The system is optimised for the requirements of print and packaging production, with a standard sensor system making it much easier to get started with successful energy management, explained the company. If required, the software can be flexibly added at any time and implementation can start immediately.

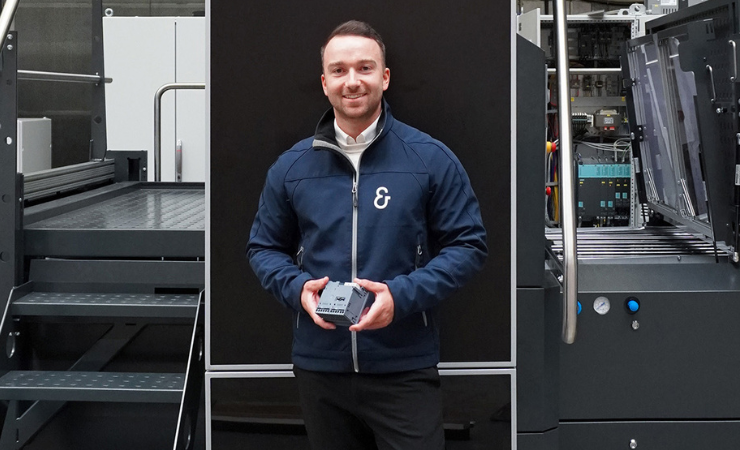

Samuel Teufel, product manager at Koenig & Bauer MetalPrint, said that energy management, particularly in metal decoration, is significant because of high-energy usages in the production process.

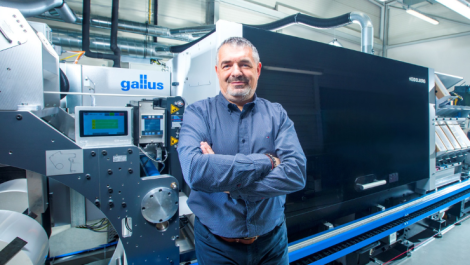

Michael Billa, VisuEnergy X product owner at Koenig & Bauer, added that utilising VisuEnergy X, the customer can view data such as: power consumption, CO2 emissions – from production to building technology. This transparent data monitoring identifies areas of savings and measures for a company, he said.

According to K&B, VisuEnergy X is the only system that displays industry-specific KPIs such as kilowatt hours consumed in relation to production output. It also provides ‘genuine’ added value, regardless of the substrate being printed. For models without sensor technology as standard, it can be either selected as an option for new machines or retrofitted.

Mr Teufel added, ‘The close collaboration between Koenig & Bauer MetalPrint and the Group’s Digital Unit has paid dividends. Together with our central unit for digital transformation, we have recognised the pressure on our customers to be more sustainable and to keep energy costs down. By integrating measuring instruments into our machines, we’re making it easier to start using an energy management system.

‘The modularity and system independence of VisuEnergy X fit perfectly into the metal decoration industry’s production environments, offering our customers real added value.’

Mr Billa continued, stating that with every new machine, customers are given the technical basis for automated recording of energy data and can put the energy management system to the test – which can be broadened to cover the entire production.

He concluded, ‘With VisuEnergy X, we’re together setting a new industry standard when it comes to efficient energy management.’