Hybrid Software has release iC3D Version 10, bringing enhancements and essential fixes, reinforcing Hybrid’s commitment to providing 3D solutions for packaging designers and manufacturers.

Heath Luetkens, Hybrid Software business manager of 3D Graphics, said, ‘Our tenth release of iC3D is a testament to our continued innovation on behalf of packaging professionals. The deep integration with our recently acquired Capture 3D technology for accurate metal can printing strengthens our comprehensive solution suite for both brands and packaging converters, delivering a high-quality suite of tools trusted by the entire value chain.’

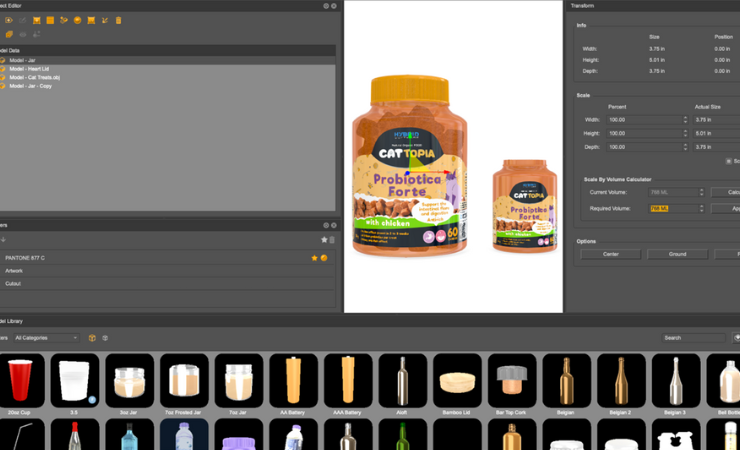

iC3D version 10 has new advancements in its advanced warping template. Integrated with Hybrid Software’s Capture 3D distortion software for metal cans, the warping template allows users to select scanned model data, set parameters for the distortion grid, and generate designs for use in Packz. This enhancement streamlines the design process for metal can packaging, ensuring supreme quality and accurate printing. Additionally, iC3D’s photorealistic live 3D viewing unlocks new opportunities for branding and innovation in metal can packaging, explained Hybrid Software.

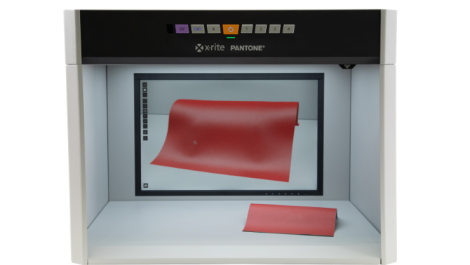

The new version has introduced an updated OpenGL viewer which now includes enhancements to material rendering, offering more realistic visuals. This viewer features tools for soft proofing and facilitates customer feedback through a secure web browser. Additionally, it integrates seamlessly with Hybrid Software’s workflow production suite, Cloudflow, ensuring a smooth and efficient production process.

A new option within Transforms allows users to adjust a model’s size using volumetric information. This feature is particularly beneficial for creating accurate bottle models, as it enables scaling based on volumetric calculations.

Hybrid Software added that the above enhancements means users of iC3D will experience a significant boost in their design efficiency and overall 3D experience.