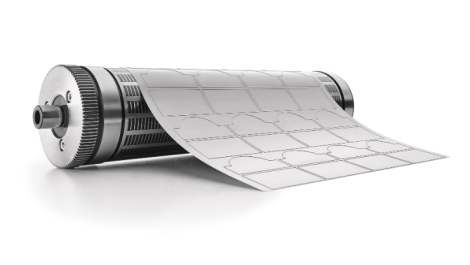

Maxcess, supplier of digital and flexo printing equipment, has launched its Tidland SmartSlit automated slitting system, that the company says ensures automatic and precise placement of slitting blades, eliminating the need for manual adjustments, reducing set up time.

Richard Provencher, global product manager for Tidland slitting and winding, commented, ‘SmartSlit is ideal for tag and label producers and narrow web converters looking to automate manual finishing operations or add finishing operations to their current lines. It is a safe, versatile, user-friendly solution to slitting operations, significantly enhancing productivity, and reducing operational costs.

‘Our automatic machinery movement minimises manual hand adjustment and reduces safety concerns and operator errors. Users get improved ergonomics and greater accuracy versus manual position alternatives. You can also store repeat jobs for reuse later. The best part is Tidland SmartSlit usually pays for itself in less than two years compared to manual systems on the market,’ Mr Provencher concluded.

The company outlined the system’s ‘unique’ features: the ability to have a maximum of 24 knives – about twice what the competition offers, Tidland claims; maximum web width of 48in (1220mm) – claimed to be nearly 50% wider than most competitors; the option to run either automated or manual; removable blade cartridges; the ability to automatically scan current slit position; and intuitive and easy to use.