A B Graphic International (ABG) has opened its new manufacturing facility in Kelleythorpe, UK, representing what it says is ‘a fresh chapter in dedication to excellence and innovation within the industry’.

The Kelleythorpe site has been fully operational since 19 August 2024 and adds to the company’s existing manufacturing premises in Carnaby, UK; Baesweiler, Germany; and Girona, Spain.

The new facility integrates ABG’s machine shop operations, and is equipped with cutting-edge milling and lathe machinery, featuring advanced equipment from Mazak, Hurco and Matsuura, with the introduction of the high-speed 5-axis Matsuura machining centre, in particular, being cited as delivering greater automation and efficiency to ABG’s manufacturing capabilities.

Marking the 30th anniversary of Vectra manufacturing, the Kelleythorpe site has also become the production base for ABG’s Vectra turret rewinder ranges. This new facility offers more manufacturing space, helping to increase Vectra production capacity, aiding in reducing lead times for customers.

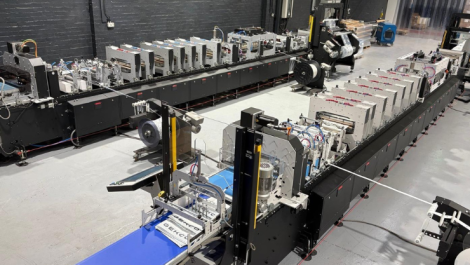

The new site also hosts ABG’s first UK demo room offering customers the opportunity to experience its technology first-hand. The room is home to the company’s complete converting line featuring a non-stop unwinder, fourth generation converter, the latest Vectra AutoSet turret rewinder, an SRI3 for slitting and inspection and an RTS sheeting machine.

The development also includes a new two-story office block, a space serving as the permanent home for teams that were previously based at ABG’s Middleton on the Wolds location, including service, parts, software and design, among other teams.

Dave Lawson, Kelleythorpe’s director, said, ‘While our Middleton site served us well for many years, the new Kelleythorpe facility ensures that ABG remains at the forefront of the industry. With this modernised space, we are better equipped than ever to produce the highest quality parts for all ABG machines, not only meeting but exceeding the expectations of our customers. This investment solidifies our position as a leader in the market, enabling us to maintain our competitive edge and continue our tradition of innovation.’

ABG is also expanding its manufacturing capabilities in Germany by doubling the capacity of its Baesweiler site to 4400sqm. This expansion is set to increase the production of SRI machines, ABG’s fleyeVision cameras, booklet machines and Horizon table rewinders, all of which will help in decreasing lead times for customers.