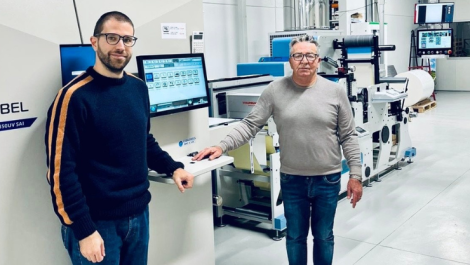

Bobst has opened a new ‘state-of-the-art’ Labels & Flexible Packaging Competence Center in Italy, with a three-day event that saw more than 200 of its customers pass through the doors.

The event took place between 8 and 10 October in Florence, on the same site that was damaged by flooding last year, giving customers the opportunity to gain a complete overview of the company’s proposition for the narrow-mid web market, including prepress, machinery, cloud-based digital platforms and final applications. Inline flexo, digital and All-in-One (or hybrid) printing technologies were all shown.

Matteo Cardinotti, head of Narrow Mid-Web Printing & Converting Product Line, commented, ‘The major investment in the Narrow Mid-Web Printing & Converting Product Line demonstrates Bobst Group’s strong commitment to this segment.’ He added that Bobst had experienced ‘exceptional growth’ in labels in recent years, and that the development in Italy included expanded production facilities and a reinforced service organisation.

Live demonstrations at the event included a Digital Master 340 press running pressure sensitive labels for the beauty sector, and a Master M5 flexo press showing single pass production of multi-layer labels, using oneECG technology and DigiFlexo automation. Meanwhile, a Master M6 flexo press was set up for medium run flexible packaging, integrated with a mid-web Novalam MV laminator.

The fast-increasing importance of software and data for Bobst was also apparent in the roles played by its Connect cloud-based digital platform and Accucheck inline inspection system. The concept of twin-PDF was put forward, in which information such as production and job data and quality reports is stored with the job file, potentially making re-use easier. In a ‘deep dive’ session, Bobst said that Accucheck will increasingly become not just the eyes but the brain also, making machine decisions based on captured intelligence.

‘Bobst has brought into reality the idea of the closed-loop workflow, from PDF to twin-PDF concept, addressing the main industry trends with easy-to-use machines, all orchestrated by Bobst Connect,’ said Mr Cardinotti. ‘Our main focus is to provide customers with complete workflows that help them overcome a multitude of market challenges, allowing them to deliver consistent and high-quality results much quicker and with low waste, without having to rely on highly skilled operators.’

Among the partners present at the open house event were Esko, Kurz, Avery Dennison, Sun Chemical, Kongsberg PCS, DuPont and Lohmann.