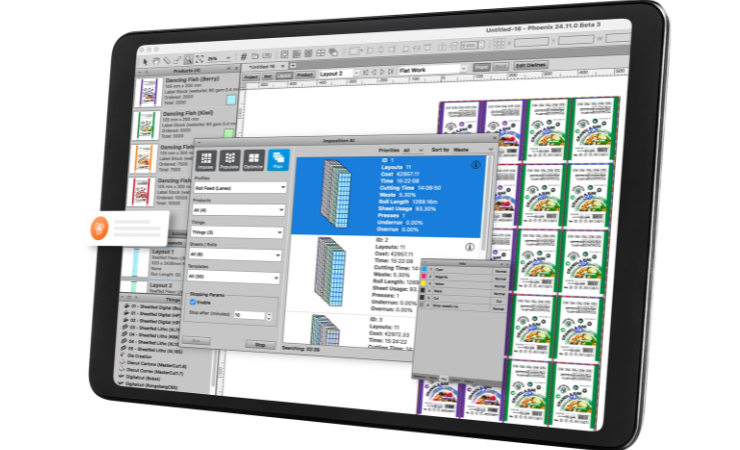

Esko has made its Phoenix pre-production software for labels and packaging available for all roll-to-roll label converters across flexo, offset and digital printing.

The AI-driven planning and estimation software helps print operators to optimise sheet and web layouts with nesting and imposition schemes that reduce waste, according to Esko. It does so by considering the ‘real-world’ capabilities of printing and finishing equipment, making the process of planning and setting up faster and more efficient.

James Mason, general manager for Print Optimization & Planning at Esko, commented, ‘Phoenix enables users to fully automate their planning and early estimation processes, replacing formerly time-consuming manual steps that were also prone to error.

‘At the click of a button, Phoenix carries out the production estimation, AI analysis of the design and equipment needed for the job – then calculates the most efficient way to produce this quantity using factors such as number of labels per reel, equipment availability, multi-reel width substrate comparison, inks and foils. It is even possible to specify whether splicing is allowed, and if so, how many reel splices might be deemed acceptable. Additionally, using custom fields we can ensure that rewind direction, core size or any technical specifications are used to correctly identify and match lane ganging candidates.’

Phoenix was showcased at drupa this year during its pre-release phase, now successfully completed. Although it can be used with a wide range of printing processes and sectors, including sheetfed, wide format and commercial print, Esko has now made the intelligent planning system available with specific roll-to-roll functionality as part of its Esko software suite. It has been built for packaging professionals, by packaging professionals, the company said.