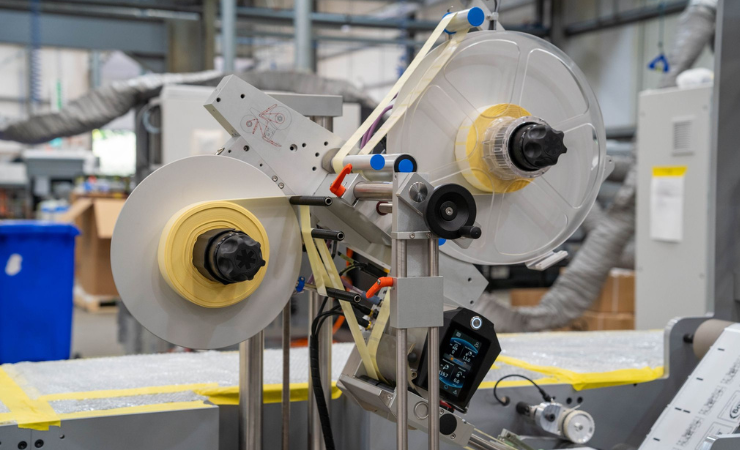

Finishing equipment manufacturer A B Graphic International has supplied US Abbott Label with a 330mm RFID converting line designed to handle high-speed RFID inlay insertion across multiple substrates, label sizes and packaging applications.

An ABG customer for over 25 years, Abbott Label operates five ABG machines. The latest investment supports multiple lanes and varied web widths, with modular designs that can be customised to specific operational needs, ensuring flexibility and scalability in RFID label production.

Mark Davenport, RFID plant manager at Abbott Label, said, ‘I feel that it’s the highest-producing, fastest solution in the market today. ABG’s equipment is rock solid. All the equipment I’ve bought over the last 24 years is still efficiently running today.’

According to ABG, RFID is transforming industries by offering seamless tracking and identification of products through a combination of microchips, antennas and RFID readers. This technology allows for optimal, hands-free tracking of assets, thereby making processes faster, more accurate and more cost-effective.

‘ABG’s advanced RFID solutions help our customers stay ahead in this rapidly evolving market,’ added Matt Burton, ABG’s global sales director. ‘By offering a range of entry-level machines alongside highly customisable systems, we actively support our customers in adopting RFID technology, whilst offering increased efficiencies and the reliability associated with ABG solutions.’